- 1,926

- 30

- 48

- Location

- Irmo, South Carolina

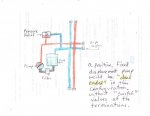

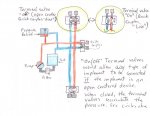

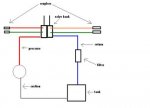

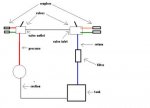

Guys, I'm looking for some ideas about how to fit hydraulics to the deuce for a variety of purposes: knuckleboom, dump bed, rear winch, log splitter, chain saws, you name it.

I have a hard top deuce with front mounted PTO winch. I recently purchased a transfer case PTO for operating a pump. Beyond that, my truck is a blank slate for adding whatever utility is most beneficial.

The threads I have uncovered in my searches were builds specifically for mounting knucklebooms or fitting dump beds. My search did not uncover any threads about making the deuce into a hydraulic Swiss army knife! (SEE?)

If anyone has suggestions, recommendations or resources to recommend for sizing and designing hydraulic systems, please pass them on. I have no experience with hydraulic equipped vehicles, but have admired a few farm tractors that were fitted with multiple circuitry (front, rear, side). I especially liked the idea of quick couplings, making the tractor a real Swiss tool. I would like to duplicate that kind of utility with the deuce if possible.

Cheers,

Rick

I have a hard top deuce with front mounted PTO winch. I recently purchased a transfer case PTO for operating a pump. Beyond that, my truck is a blank slate for adding whatever utility is most beneficial.

The threads I have uncovered in my searches were builds specifically for mounting knucklebooms or fitting dump beds. My search did not uncover any threads about making the deuce into a hydraulic Swiss army knife! (SEE?)

If anyone has suggestions, recommendations or resources to recommend for sizing and designing hydraulic systems, please pass them on. I have no experience with hydraulic equipped vehicles, but have admired a few farm tractors that were fitted with multiple circuitry (front, rear, side). I especially liked the idea of quick couplings, making the tractor a real Swiss tool. I would like to duplicate that kind of utility with the deuce if possible.

Cheers,

Rick