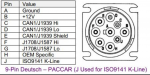

I have been through all the connections on transmission , inside kick panel disconnected reconnected ecu, looked inside ecu no corrosion, and front of truck connections, Keep getting code D1-6600 . Down shifts are pretty hard when I let off the gas all the way. 6600 is coming up as a serial communication issue. Any other places I should check? Found a schematic but not sure which wire is for communication.

2001 WTEC3 tcu-29541151

2001 WTEC3 tcu-29541151