tim292stro

Well-known member

- 2,118

- 41

- 48

- Location

- S.F. Bay Area/California

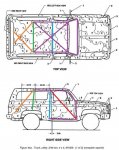

For a K5 Blazer (M1009) I can see using more than 4 "sticks", especially if you want to retain the rear seat... One 12-16' stick would be your main "hoop" in the B-pillar, one 5-6' stick would be a diagonal in the hoop (not even meeting the minimum structural needs IMHO though) - two crossing in an "X" would be better, but would complicate getting in the rear seat by flipping the front seat(s) forward. That would only cover roof-crushing and side-to-side "racking" in the b-pillar area, wouldn't touch front-to-back racking, and wouldn't protect any back seat passengers. IMHO the initial polygon shape of the cage is easy and doesn't require much steel, but making it strong enough not to become a hazard (I have this awful fear of amputation/crushing by my own safety device construction), takes about as much steel if not more than the initial shape.2.409# per foot x 32 =77.08 so, yes! My 75# guess was off the cuff but now it's calculated. Is 4 sticks and estimate?

Side-to-side racking in a house "polygon" - it's "shear failure" without a break: