As I am getting ready for the Super single project, I thought it would be a good idea to inspect the brakes while I have everything apart.I noticed that the right rear drum was gooey.I removed the drum, and to my dismay, it appears that the axle seal is leaking.I checked the wheel cylinder it is dry.It looks like there is a small chunck out of the seal.What am I going to find when I pull the hub? What keeps the gear lube out of the wheel bearings?I would like to know what to expect. can anybody recommend an afffordable supplier? I would like to get this buttoned up soon.  Thanks

Thanks

-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Big Greasy Brake Question

- Thread starter derby

- Start date

More options

Who Replied?Knucklehead

New member

- 142

- 0

- 0

- Location

- Spencer, MA

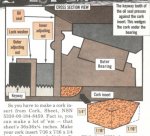

There are 2 seals. The inner and outer. The inner seal will stay mounted on the spindle when the drum assembly is removed. The outer seal sits between the spindle nuts and the outer wheel bearing.Both seals are one piece rubber and metal. The outer seal will come out easily, the inner will remain on the spindle and will have to be pryed off.There is one problem with 5T bearings that I have run into.There is a groove on top of the spindle a tab for the spindle nut lock rides in. This grove must be sealed to prevent oil leakage. It was origanally pluged with a piece of cork that came with the outer seal, but RTV will work very well. I have found this space to be left open on several trucks that i have had and leaks resulted.

When replacing the inner seal mount it onto the drum so it is flush and it is retaining the inner wheel bearing. Also be careful when replacing the drum so the seal will not be damaged. I sed to slide the drum off/on with both tires mounted. But now I use a $50 motorcycle lift.

When replacing the inner seal mount it onto the drum so it is flush and it is retaining the inner wheel bearing. Also be careful when replacing the drum so the seal will not be damaged. I sed to slide the drum off/on with both tires mounted. But now I use a $50 motorcycle lift.

Knucklehead

New member

- 142

- 0

- 0

- Location

- Spencer, MA

Sorry, suppliers, Memphis Equipment. Saturn Surplus, Whiteowl, TNJ Murray.

- 10,350

- 75

- 48

- Location

- Meadows of Dan, Virginia

This should help you get the picture.

http://www.steelsoldiers.com/index....cork_seal&name=gallery&include=view_photo.php

http://www.steelsoldiers.com/index....cork_seal&name=gallery&include=view_photo.php

Attachments

-

148.4 KB Views: 870

- 1,716

- 3,846

- 113

- Location

- Hidden Valley, Az

Don't forget to check the little vent on the axle housing as well, it can get stiff and let pressure build to help that 90-W out all over. It should let air out but not water/dust in if working properly.

dg

dg

My brake shoes with the leaks were pretty oily. I soaked them in mineral spirits for about 4 days. It leached the oil out of the pads...seem to be fine now. I started using brake cleaner but I kept getting oil out of the shoes. The soaking seemed to do the trick...didn't harm anything either.

rmgill

Active member

- 2,479

- 14

- 38

- Location

- Decatur, Ga

I'm starting to think that replacing those vents with tubes to the truck's vent system makes more sense. Both from a reliability stand point and from a better fording capability standpoint. I can't be certain if having them pressurized a few psi is a good idea or not though. I'm probably going to run a 3/8" tube back from the main breather line to the rear axles and add those to the vent system with a couple of hose fittings added. The front will take a bit more work to do. The nice thing about the rear is that it's just a straight shot of hard line then a Branch Tee for the two axles and some hose. Crimp on connections should be easy enough too.

- 4,038

- 119

- 63

- Location

- Ponchatoula LA

now that is one to remember when i ckeck my brakes thanks Tim

Ok,got my new seals today,pulled the hub to get`r done.I found two areas of concern. 1 the inner race has some slight abraisions in two spots.just enough to feel with fingernail.they run accros the race maybe 3\8".replace race and bearing? 2 the wheel cylinder actuator? the part that contacts the shoe from the wheel cylinder.the pins that contact the shoe are a little bent.is this normal or abused? where is the best and cheapest place to purchase them? I got the seals from Memphis Equip.sorry I don't have pic's can't seem to figure it out.

I found similar damage to some and more severe to others. I chose to replace ALL bearings and races. I also replaced ALL wheel cylinders. If I'm gonna go down this far I might as well. Regarding the slightly bent pins, I have the same thing. Shouldn't be an issue.

Towman2277

New member

- 507

- 0

- 0

- Location

- Saraland, Alabama

If it was worth tearing down to you, i'd fix it right and be done with it. I've discovered hairline scratches in races that become serious wheelbearing failure fast!! Hate to see them duals pass ya' at a stoplight!

If it was worth tearing down to you, i'd fix it right and be done with it. I've discovered hairline scratches in races that become serious wheelbearing failure fast!! Hate to see them duals pass ya' at a stoplight! - 110,898members

- 165,318threads

- 2,326,332posts

- 1,335online users