So I started a new thread to illuminate the importance of checking "shake" in Humvees. This was my first so I assumed it was normal.

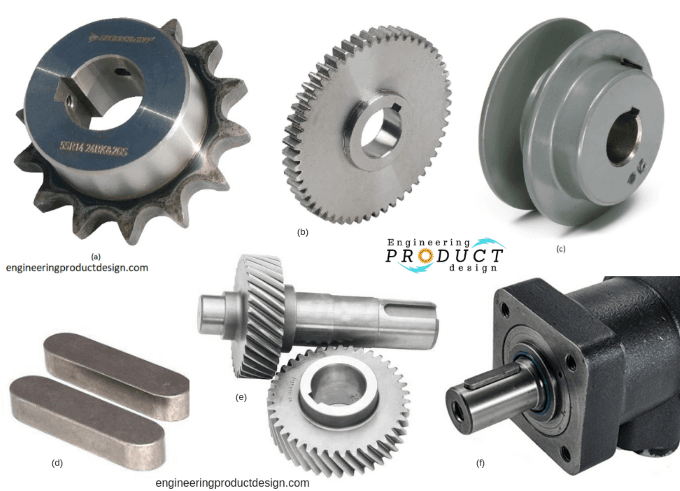

I removed my crank pulley and harmonic balancer this weekend, which by the way was a beeotch. Once removed I noticed the key channel was intact only toward the end of the tube of the balancer. The area toward the front was completely warn and the metal was etched away. Once I went back to examine the crank, I noticed the key was missing and there was bite out of the metal where it used to be. Turns out the vibration was caused by the balancer's rotation due to the missing key, throwing the weight off time.

Guess it's time for a new engine.

I removed my crank pulley and harmonic balancer this weekend, which by the way was a beeotch. Once removed I noticed the key channel was intact only toward the end of the tube of the balancer. The area toward the front was completely warn and the metal was etched away. Once I went back to examine the crank, I noticed the key was missing and there was bite out of the metal where it used to be. Turns out the vibration was caused by the balancer's rotation due to the missing key, throwing the weight off time.

Guess it's time for a new engine.

Attachments

-

48.8 KB Views: 79

-

32.1 KB Views: 79

-

33.5 KB Views: 78