The knurled section of the starter bolt countersinks into the block starter bolt hole to clearance itself to create a non tolerance fit. That it is why new bolts should be used when replacing starter. Starter clearancing are very tight new, however the mounting surfaces on used rebuilt starters are sometimes machined for squaring surface to block fit then requiring starter shims. If bolt holes are oversize then another starter is advised.

Twist off bolts are usually from over tightening bolts, bolt stretch, or from side torque force. They are designed like sheer bolts to where they break before damaging the block.

Unbolting starters are critical on how they are lowered while removal is done. You should always hold starter against block until bolts are removed so that bending of the bolt at the start of threads are not damaged.

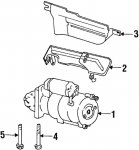

A misunderstood critical part of the engine that takes precise installation, and extra care is needed.