farmerklaassen

New member

- 8

- 0

- 1

- Location

- Rogers, AR

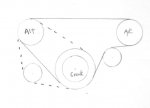

Recently I've been getting ready to install A/C. Looking at all the options and dying from sticker shock. Upon investigation I cannot understand why anyone would add a pully to the front of the crank pully and not just use the crank pully itself. I've called Gates Rubber and was told by an engineer that the back bend on a 1/2" v-belt is a 4 1/4" diameter idler pully. So what I'm thinking is just using a 2 belt compressor clutch and longer belts, put an idler pully between the crank and A/C to ensure I get enough engagement on the crank pully . Does anyone see anything wrong with this plan? Has everyone else just overlooked this simpler and less expensive way of doing it? I'm looking for feedback, I'm not trying to offend anyone.