Oerthedge21

Member

- 250

- 20

- 18

- Location

- Northford CT

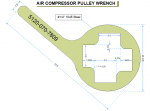

My compressor base gasket recently sprung quite an oil leak. Finally bought a new gasket and went to out it in, only to realize one if my compressor wrenches is gone, specifically the big square shaped one. Also noticed that my pulley is cracked in front where the bolts run through it. My question here is 1) can anyone give me the measurements for the wrench so I can make a new one? And 2) does anyone know of a place to get a new compressor pulley for a reasonable price? I checked a few sites but they wanted around 100$, which I thought was absurd, but I could be wrong. Are they really that valuable?