JasonS

Well-known member

- 1,665

- 195

- 63

- Location

- Eastern SD

Continental developed a 350HP engine based on the 478 cubic inch "multifuel" engine.

Some interesting features other than the power output:

Some interesting features other than the power output:

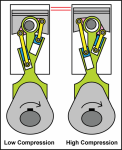

- Variable compression ratio: a high of 17:1 and a low of 10:1

- The BSFC was 0.380 lb/ hp*hr which is actually better than the LDS engine

- Still using the American Bosch PSB injection pump

- Aftercooler built into the intake

- Aluminum heads, oil filter housing, and rocker covers

Attachments

-

11.1 MB Views: 56