Freedom Land Clearing

Member

- 33

- 26

- 18

- Location

- Montoursville, PA

Roger on reducing to 125.You were able to work the solenoids using the jumpers right, so they are probably OK. The best test for the wet tank switch is at the CTIS controller connector. When the tank goes over 117 PSI you snould see it close and complete a low resistance circuit between pin T in the connector and ground.

I would work that governor set point down towards 125 PSI.

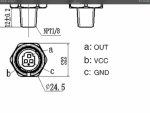

it could be that you have a bad pressure sensor on the PCU. While you have the PCU apart, unscrew the sensor and inspect it for any debris in its sensor port. You could also check resistance between the pins in the CTIS controler connector and the pressure sensor connector at the PCU install location. Pins j, b and c (lower case) should connect to pins A, B and C respectively in the pressure sensor transducer connector at the PCU.

You could also probe the wires thru the insulation with a pin to the pressure sensor with controller and sensor connected and powered. it is a 0-5v 0-100 PSI sensor. The controller sends 5v and ground to two of the pins on the sensor and the sensor returns a 0-5v signal based on the pressure it senses. 5v divided by 100 = .05v per pound of pressure, so 14PSI of atmospheric air pressure should yield ~.73V on the sense wire…

contact Superman here on steel soldiers, he had PCU rebuild parts. Great guy to work with!

I did take take that sensor off the PCU…and it was locked on there right. The only thing in it was a little moisture. I short it with some spray and reinstalled.

At next opportunity I’ll check continuity. If that all checks out, do you suggest a new sensor? If so, do you happen to have a part number?

After looking at your manual setup, I’m inclined to go that route due to it simplifying the system.

Thanks again for your help!

John