cryptofile

New member

- 18

- 6

- 3

- Location

- Missouri

Just won a M1123 on gov planet and am waiting for the paper chase to work itself out so in the meanwhile I'm doing a lot of learning.

So I do some fabrication and I'd like to make my own C pillar for this thing.

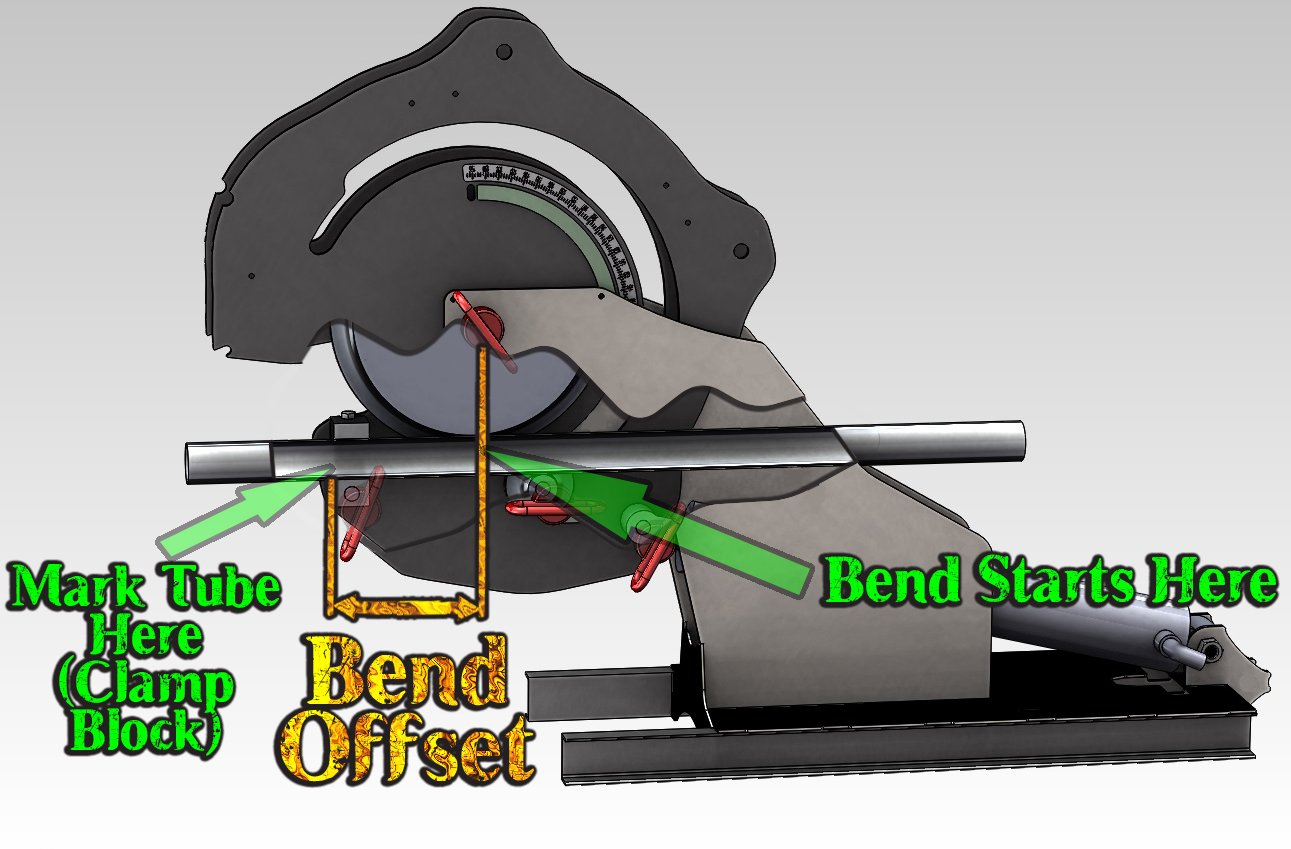

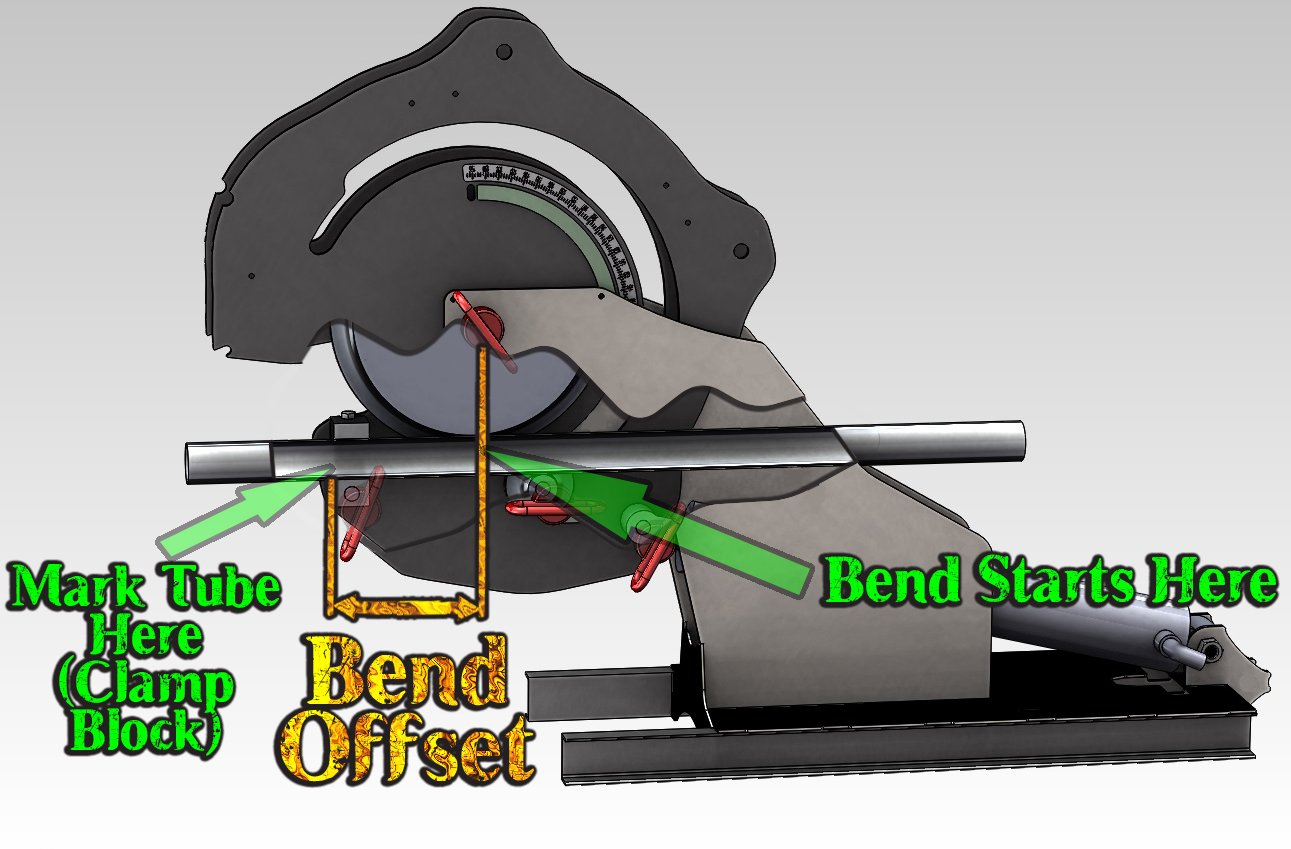

I found a quality source for aluminum and steel tubing and plan to use a tube steel bender to make my own C pillar.

www.roguefab.com

www.roguefab.com

Two questions:

1. Does anyone know what the internal or external radius is on the C-pillar curves?

2. What is the exact angle between the sides and the top?

Thank you for any insights related to custom C-pillar construction.

So I do some fabrication and I'd like to make my own C pillar for this thing.

I found a quality source for aluminum and steel tubing and plan to use a tube steel bender to make my own C pillar.

Tube and Pipe Bending 101 | Rogue Fabrication

This is currently being updated to add new offsets for the M601/605/625. Please let us know if you have any questions. This is our page where you can learn how to bend tubing accurately with...

www.roguefab.com

www.roguefab.com

Two questions:

1. Does anyone know what the internal or external radius is on the C-pillar curves?

2. What is the exact angle between the sides and the top?

Thank you for any insights related to custom C-pillar construction.