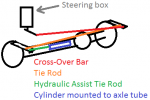

what you cant see in the picture is the cylinder is mounted on tabs welded to the axle on the drivers side next to the spring mounts, so there is not side to side movement on the cylinder. With only one end tied down, the other was free to move in what ever direction the tie rod will take it. This strap I built simply controls the movement of the free end of the cylinder.

Olly Hondro, your drawing will not work unless you have a lot of lift. The steering arm does not have that much angle. I have 5 inches of lift and my steering rod is parallel with the tie rod. The cylinder has to be behind the tie rod or otherwise it will have nothing to mount to. The tie rod and steering arm are both in front of the axle putting the cylinder in front of that leaves the cylinder mounted over air. The axle is 6 inches back.

Also, you want the cylinder parallel with the tie rod so it is pushing and pulling in the same direction that the tie rod is supposed to go. With the cylinder at an angle, it is going to be pulling the tie rod down on left turns and trying to push it up on Right turns. The other issue with your drawings is that you will have to build a new arm for the passenger knuckle at this time I do not know anyone who makes a knuckle extension for the hydro cylinder. And the tabs for the other end of the cylinder will have to come forward and up to get the cylinder parallel with the tie rod.

I did not reinvent the wheel with my hydro assist system. I purchased the PSC kit that ORD sells along with the ORD cross over high steer system. After it was installed I saw a need to fix a problem that ORD or PSC has not addressed.

I called them to discuss it and the answer both had were to cheat the tie rod ends so that they limit the travel by having them turned opposite each other on the tie rod thus limiting the rotating slop.

I did not like this, it caused more stress on the tie rods than should be there and the tie rods are not meant to be stressed to their rotating limits.

I installed the system per the directions, got everything working to find the tie rod rotation issue. I called Ord and PSC and they did not have a solution, just told me most people just live with it that way.

I then determined that both ends of the cylinder have to be controlled but the rod end needed some movement. I built this fixed strap with pivot points and it fixed the problem.

I welcome those who wish to build their own Hydro assist system, maybe they can make one better than what is already out there. I am simply sharing my experience with the kit I installed. I am sharing this with ORD. I think they should sell it with every kit they sell, I can promise all here that it is a necessary improvement when installing the PSC kit on a D60 axle with cross over high steer.