UPFINN

Member

- 231

- 4

- 18

- Location

- Ishpeming Michigan

I am looking for good info on how to properly use a bottle jack for lifting a axle on the m35a2.

I need to swap out a old tire with a new one on the front axle, and check brakes on the rears.

I have a 12 ton bottle jack with a max lift height of 18 1/2 inches and 6 ton jack stands. The basic issue bottle jack for the deuce had a lift height of 19 1/2 inches.

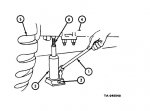

I have always used floor jacks for axles, or bottle jacks on the frame of a smaller car or truck. My question is, where is the best place to put the bottle jack on the 2.5 ton axles? My plan right now is to put the jack on a large block of wood for extra height, then position the jack under the mounts for the suspension, with a piece of wood between the jack head and the suspension/leaf spring mount. It seems to me that as the axle angle increases while jacking up one side, the bottle jack will slip out. Hopefully the block of wood between the jack and axle will "dig in" and secure it.

I have also seen some jack up an axle from the bottom of the differential. I would think this could cause damage.

There is also clearance issues with the jack stands. I would rather have the jack stands closer to the tire being removed, or outside of the suspension mounts, but instead will have to put the stands very close to the differential housing. I have the same issue with wood cribbing/blocks.

Also, for jacking up the middle axle, I will have to crawl under the truck where the spare tires goes to operate the jack. Is this safe? Of course the truck can't fall on me, but I imagine the jack or stand could slip and the truck could roll. I will use wheel chocks.

Are my methods correct/safe? I feel that there must be a TM for this I never knew about.

I need to swap out a old tire with a new one on the front axle, and check brakes on the rears.

I have a 12 ton bottle jack with a max lift height of 18 1/2 inches and 6 ton jack stands. The basic issue bottle jack for the deuce had a lift height of 19 1/2 inches.

I have always used floor jacks for axles, or bottle jacks on the frame of a smaller car or truck. My question is, where is the best place to put the bottle jack on the 2.5 ton axles? My plan right now is to put the jack on a large block of wood for extra height, then position the jack under the mounts for the suspension, with a piece of wood between the jack head and the suspension/leaf spring mount. It seems to me that as the axle angle increases while jacking up one side, the bottle jack will slip out. Hopefully the block of wood between the jack and axle will "dig in" and secure it.

I have also seen some jack up an axle from the bottom of the differential. I would think this could cause damage.

There is also clearance issues with the jack stands. I would rather have the jack stands closer to the tire being removed, or outside of the suspension mounts, but instead will have to put the stands very close to the differential housing. I have the same issue with wood cribbing/blocks.

Also, for jacking up the middle axle, I will have to crawl under the truck where the spare tires goes to operate the jack. Is this safe? Of course the truck can't fall on me, but I imagine the jack or stand could slip and the truck could roll. I will use wheel chocks.

Are my methods correct/safe? I feel that there must be a TM for this I never knew about.