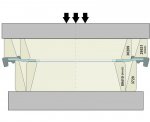

.....for the bottom (seal inside face) I used a stock #3720 (93.3x23.81). Centered inside the same fits a HM89410 (76.2x23.0) with its height reduced to 22.7. For the top (seal outside) a stock #30209 (85.0x16.0) in combination with a modified 29521 (110x 19, height reduced to 14.6) works best.

G.

WOW, Gerhard, THANK YOU very much for this info! While rehabbing a replacement rear axle on my in-progress Deuce, the wheel seals were blown on this axle, and they are the newer "Newstar" design. Trying to find NOS outer seals is next to impossible, and here in the desert rubber doesn't last long anyway. So, I thought it best to follow your advice on using bearing cups to modify the Newstar seals.

I managed to find 3 of the 4 bearing cups at my local NAPA store, all NAPA house-branded but manufactured by SKF. Part numbers are

HM89410;

30209-C (couldn't order it as cup alone, had to order it with the bearing included for some reason), and

BR3720.

However, trying to find a 29521 was almost impossible...I found one listed on Summit Racing's site, and when I talked with those folks they said that it was an older, obsolete style cup that they special-order direct from Timken, and when completed will ship directly from Timken...earliest it would ship is 3 weeks from now, but I didn't want to wait so I had my NAPA guy find something with an inner diameter that would fit over the Newstar outer seal (overall inner diameter is exactly 3.5-inches).

We checked every bearing & cup catalog that was in the store, and I even searched through Timken's & Federal-Mogul's catalogs online, but we couldn't find any cross-reference for a 29521. Not even the NSN info with alternate part numbers helped.

What my NAPA guy did find was a NAPA house-branded SKF bearing cup with a part number of

JLM710910. It has an overall height of just over 18mm, so it took some judicious grinding to lower it to 14.6mm. But it worked perfectly!! I tried the setup out on my Newstar outer seals, and this setup worked PERFECT. All my outer seals now look just like G's above.

I am very happy, thank you so much Gerhard!! This should help prevent the seemingly-perpetual leaky & hot hubs so many of us are encountering.