Thanks

DieselAddict and Guyfang,

Things done today:

1. New Main Fuel water separator replaced wix 33583.

2. Removed air filter, no change in operation. Removed Air Cleaner Assembly heater was clean. Air intake duct had some soot in it.

3. Valve Clearance Adjusted, was off by a bit . Set to TM spec.

Seem to be less noisy now, still have black smoke under load. 1500W+

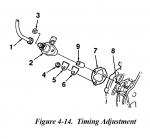

4. Attempted a Fuel Injection Pump Adjustment. see below for remarks

--Fuel Injection Pump Adjustment--

I removed the high pressure fuel line moved it over to side. Flywheel cover removed and I opened the actuator. I rotated fly wheel clockwise to T meets V mark. No fuel being pumped observed so I rotated the fly wheel around 6 times no fuel still, I recorded me rotating it 4 more time this time with electric fuel pumps on still no fuel. Am I doing something incorrectly? This is where I halted my progress for the time being.

I did not have this smoking until after I pulled the engine and replaced the fuel line. I'm starting to think some thing my of got caught in the injector pump. maybe when this is running it gets a enough fuel for 1500W but not 3000W. Maybe the injection lose pressure it needs at this demand and the fuel wont atomize. While I was turning fly wheel I push the decompression lever to allow me to turn the wheel more easily.

https://youtu.be/cHnzts61BZg