- 4,207

- 3,191

- 113

- Location

- Near Austin, Texas

For some time I had been 'sorta looking' for an M151A2, as I wanted to add a small vehicle to the herd and I drove those in the Marines way back in the last century.

Back in November Roboskid sent me a link to an ad for several vehicles, and said "I know you want an M151, but look at the Mites!".

There were three in the picture, and those things just grabbed at me, so I called the seller, Jim.

Turned out he was also an old Marine, and while he was going to sell his vehicles, he said they were like his kids, he wasn't going to sell them to anyone but "the right home", preferrably another slightly younger old Marine. He'd already had a few calls that started with "That would be a great hunting buggy on the ranch...", he cut them off with an immediate and firm "Nope!".

I told him I was a collector, and that vehicles have a pretty soft life with me.

("Gatherer" might be more accurate than "collector". Collectors usually have certain criteria they look for, a theme; I simply go with "Oooh! I like that!").

So, I made arrangements to meet up with Jim at his place near Houston. Sid (Roboskid) wanted to go along, I warned him that after the phone conversation with Jim, I suspected it was going to be a lengthy day. Sid usually gets straight to business, bam bam bam, when he's making a deal, but I told him this deal likely wasn't going to be quick at all.

In short, we met up with Jim at 10am, looked at all his vehicles (he had a bunch!), went and had a two hour lunch, and didn't talk a word of business until around 4pm.

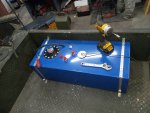

I apparently passed the adoption interview because we left with me owning one Mite, an M715, and a Coot.

Cheers

Back in November Roboskid sent me a link to an ad for several vehicles, and said "I know you want an M151, but look at the Mites!".

There were three in the picture, and those things just grabbed at me, so I called the seller, Jim.

Turned out he was also an old Marine, and while he was going to sell his vehicles, he said they were like his kids, he wasn't going to sell them to anyone but "the right home", preferrably another slightly younger old Marine. He'd already had a few calls that started with "That would be a great hunting buggy on the ranch...", he cut them off with an immediate and firm "Nope!".

I told him I was a collector, and that vehicles have a pretty soft life with me.

("Gatherer" might be more accurate than "collector". Collectors usually have certain criteria they look for, a theme; I simply go with "Oooh! I like that!").

So, I made arrangements to meet up with Jim at his place near Houston. Sid (Roboskid) wanted to go along, I warned him that after the phone conversation with Jim, I suspected it was going to be a lengthy day. Sid usually gets straight to business, bam bam bam, when he's making a deal, but I told him this deal likely wasn't going to be quick at all.

In short, we met up with Jim at 10am, looked at all his vehicles (he had a bunch!), went and had a two hour lunch, and didn't talk a word of business until around 4pm.

I apparently passed the adoption interview because we left with me owning one Mite, an M715, and a Coot.

Cheers

Last edited: