- 6,987

- 2,523

- 113

- Location

- Montevideo/Uruguay

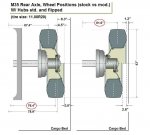

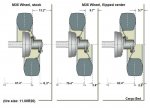

Sorry if this all created some confusion.... it is that sometimes we were comparing distance between hub mounting surfaces i.e. after flipping rear hubs...., then we speak about track width which is the distance between wheel/tire centerlines (like in my last diagram)............ it looks like flipping the centers on the front wheels and running the rear hubs stock with the outer stock wheel would equal about the same track width. .................

...........

See dimensions below and compare the numbers encircled red, hope that answers your Q.

G.

Attachments

-

51.4 KB Views: 144

Last edited: