SuperV

New member

- 7

- 4

- 3

- Location

- Knoxville, TN

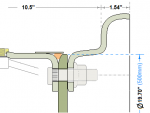

I know, I'm pretty late to the game here. I'm wanting to run 395s and have acquired a very reasonably priced pair of LMTV wheels (still looking for the rest). I have seen the threads where "peashooter" had made some adapters that bolted to the perimeter studs to allow someone to run these on a 2.5 ton 6x8.75 lug truck. I know he doesn't make them anymore. I'm hoping that he'll see this and respond. I've seen the pictures and drawings, but is there a file floating around out there for the adapters that I can take to a local shop to have cut? Can I purchase the file from peashooter? MRAP wheels are much more expensive and I don't like the adapter as much. With the right cut and using the perimeter bolts makes for a cleaner look. This is what I'm going for, so the LMTV wheels are a better option for me.

Can anyone help? Thanks in advance. Also, I searched and can't seem to find the file. I did save the PDF, but it doesn't seem to have all of the dimensions.....or am I just too dumb to understand what's on the PDF??

Can anyone help? Thanks in advance. Also, I searched and can't seem to find the file. I did save the PDF, but it doesn't seem to have all of the dimensions.....or am I just too dumb to understand what's on the PDF??