KaiserM109

New member

- 1,108

- 4

- 0

- Location

- SE Aurora, CO

This is a follow up on http://www.steelsoldiers.com/showthread.php?t=29481&highlight=deuce+start

It is an understatement to just say that I like to take things apart. I started at the age of 3 by disassembling my mother’s watch with a hammer. I often tear into things just to see how they work. I have voided many warrantees with a screwdriver.

I pulled the non-working in-tank fuel pump out of my deuce and was working with it to see if I could get it functional again. I got it to run, but not smoothly. I guessed that the brushes were probably worn out and if I could replace them and maybe clean up the commutator, I could re-install it. I was right, at least about the brushes, but it will never see the insides of a fuel tank again. One brush was completely gone while the other was less than 3/16 inch thick.

What I found was very interesting, not so much for how it failed, but for how the pump is built. A quick aside, I have been tearing into automobiles for longer than most of the readers here have been drinking from a glass. As a rule when I get into a light assembly or something else I usually find badly corroded or rusted metal. When I changed taillight bulbs on my ’66 deuce I was surprised at how new everything inside looked. It had been properly built and then properly sealed. The screws that hold the lense on even have clips to keep them from getting lost in the mud.

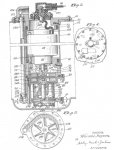

The pump is enclosed in a non-ferrous stainless steel housing that is as complete as an egg shell. I found NO SEAMS, only the hole where the wire comes out. I would really like to see how they made it!! I ground a rib off to get it open.

Not even the motor shaft comes out. It is coupled with the centrifugal pump via magnets, hence the non-ferrous housing. COOL!! Inside the housing is a magnetic disc that revolves close to a flat housing. On the outside of the housing there is another magnetic disc that is connected to the actual pump that is lubricated with the fuel. The coupling strength is about 20 to 30 inch pounds of torque, plenty to kick the fuel up the lines.

The rest of the motor was much like any other motor, it has oilite bushings and carbon brushes. The brush wires are riveted in such a way as to make them nearly impossible to change and the commutator is pretty much used up. Where most American cars are designed to last about 10 years, this is built to last about 20. I think the government got it’s money’s worth.

My recommendation to anyone with fuel pump problems is to buy a new one. A motor can test perfect until just before the brushes fly out of the holder. I have never walked away from a truck in the woods because I am conservative about maintaining critical parts and I'm too stove up to start now.

If anyone is interested, I can post pic’s of the torn down motor.

Arlyn

Colorado

It is an understatement to just say that I like to take things apart. I started at the age of 3 by disassembling my mother’s watch with a hammer. I often tear into things just to see how they work. I have voided many warrantees with a screwdriver.

I pulled the non-working in-tank fuel pump out of my deuce and was working with it to see if I could get it functional again. I got it to run, but not smoothly. I guessed that the brushes were probably worn out and if I could replace them and maybe clean up the commutator, I could re-install it. I was right, at least about the brushes, but it will never see the insides of a fuel tank again. One brush was completely gone while the other was less than 3/16 inch thick.

What I found was very interesting, not so much for how it failed, but for how the pump is built. A quick aside, I have been tearing into automobiles for longer than most of the readers here have been drinking from a glass. As a rule when I get into a light assembly or something else I usually find badly corroded or rusted metal. When I changed taillight bulbs on my ’66 deuce I was surprised at how new everything inside looked. It had been properly built and then properly sealed. The screws that hold the lense on even have clips to keep them from getting lost in the mud.

The pump is enclosed in a non-ferrous stainless steel housing that is as complete as an egg shell. I found NO SEAMS, only the hole where the wire comes out. I would really like to see how they made it!! I ground a rib off to get it open.

Not even the motor shaft comes out. It is coupled with the centrifugal pump via magnets, hence the non-ferrous housing. COOL!! Inside the housing is a magnetic disc that revolves close to a flat housing. On the outside of the housing there is another magnetic disc that is connected to the actual pump that is lubricated with the fuel. The coupling strength is about 20 to 30 inch pounds of torque, plenty to kick the fuel up the lines.

The rest of the motor was much like any other motor, it has oilite bushings and carbon brushes. The brush wires are riveted in such a way as to make them nearly impossible to change and the commutator is pretty much used up. Where most American cars are designed to last about 10 years, this is built to last about 20. I think the government got it’s money’s worth.

My recommendation to anyone with fuel pump problems is to buy a new one. A motor can test perfect until just before the brushes fly out of the holder. I have never walked away from a truck in the woods because I am conservative about maintaining critical parts and I'm too stove up to start now.

If anyone is interested, I can post pic’s of the torn down motor.

Arlyn

Colorado