Which pump are we working with ? I am old school to keep the HumV pump part factory Chevy / Delco / Carter . They work well and understood.

Haven't had priming problems with a quality lift pumps. (no leaky lines) Now the internal pump/checking valves could get gummed up gunk without pre-filter. My reasoning for the filter described, is the sock design, in-tank with its ability to bypass if clog with algae goo is getting closer to the engine.

TWO, I don't want to mess with dropping the tank AGAIN and have questions

of the need for a tank sock. With the clogged inline check valves being bypassed... drop in a little cheap filter there and clog it up LOL

If for poor fuel and algae goo or maintenance, pull the drain plug and pressure / steam the poop out of tank and dry. (disconnect the easy fuel lines first)

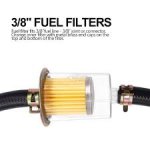

Concerns of fuel flow was a thought

thru the little outboard pre-filter. Testing in place one can easily observe the flow of fuel at WOT. So best to change it timely (cheap & easy) PMCS. Clear to see, metal ones too. If having to force fuel... I think time to change. Should flow freely

I am a little more concerned with the crap fuels blends causing bio-microbiological formations hiding in the tank, multiplying and going for a ride to the IP.

Using chemical agent to lube and kill and preserve and a "mechanic in a can" is very important.

Gear pump to make hamburger out of the algae... that's a idea, lol. Will it squeeze 4 microns of goo and catch it in the filter?

What's for lunch? Chinese food, CAMO