BimmerPower

Banned

- 101

- 0

- 0

- Location

- Mystic, CT

Hello all. First off let me start off by saying that I have been reading these forums for some weeks now and am amazing by how much information there is on here. I just recently won a GL auction for an M35A2 in great condition here in RI and plan on picking it up as soon as my EUC clears. Since I find myself checking constantly clicking on the GL site and refresh page here on steel soldiers every 10 minutes, I figure I'd like to do something a little more production with my time.

I find that there is a lot of information on these forums but that even with using the Search function, everything is scattered and relatively had to find. What I would like to is kind of organize some general information for not only myself, but for others as well. I think that it would be a great learning experience for me, we would all come up with a nice printable PDF (that I would make) and it would cut down on some of the newbie posts.

The first list I would like to start on is a Recovery manual that states what to bring (ie. items on the great list) and how much/how to get the vehicle ready for recovery. I would like to include in each category what type of fluid/lubrication to use and how much is needed. When everyone says top off all fluids, which fluids and where. Here are the topics I would like to cover:

- Engine Oil

- Transmission

- Axles

- Air System

- Differentials

- Brakes

- Transfer Case

- Stearing Gear

Side Notes for:

- Oil Filter

- Fuel Filter

- Fuel Additives

- Oil Additives (Diesel Kleen/Diesel 911)

What do you all think? I'd like to include pictures as well for a "Recovery for Dummies" manual. Cheers!

** I've edited the original post and am placing the work in progress here. Edits, additions and modifications will be made frequently and when needed:

Oil/Engine Lubrication

- 1 Case of 15/40 Engine Oil

- Slick 50 Turbo Formula

- 5 Gallon Pale of GL-1 or GL-5 Gear Oil good for Yellow Metal (Napa # SUS52)

- Engine Oil Filter (Napa # 1133)

- Oil Filter Gasket (Napa # 5119)

- Grease gun for chasis lub with extra tubes

- Pump for GL-1 Gear Oil

**For Synthetic use**

- **Amsoil 15w40 Diesel Marine Oil**

- **Amsoil 80w90 diff oil (reg) for diffs, transmission and transfer case**

- **Amsoil Synthetic Grease**

Lubrication Notes:

- Add Slick 50 to oil before cranking to aid turbo lubrication

- Check Transmission Oil - When filling the transmission with the side plug, fill until the fluid goes to the first knuckle on your index finger. Don't actually fill-to-spill or it will be slightly over-serviced.

- Check Transfer Case Oil - Knuckle fill appropriately with GL-1

- Check Differential Oil - Knuckle fill appropriately with GL-1

- Drain and refill transmission, differentials and transfer case as soon as recovery is complete

Cooling System:

- 2 Gallons Anti-Freeze

- Distilled Water

- Radiator Cap (Napa # 703-1422)

- Thermostat (Multi-fuel Napa # 358-180)

Air System

- Air Filter (Napa # 2837)

- Alcohol/Methanol

Air System Notes:

- Open air tanks and remove water and crud from system.

- Air Compressors: One is a single cylinder, the round one (Midland). The other is a two cylinder that looks like a figure 8 (Bendix). Both are air cooled.

- Taken from Cleb on SS: On the airpack, frame side, there is an airline coming in, that goes to a flange, which is held to the airpack by 4 bolts. I had a slight air leak I could feel around that area (only held about 60psi running). After tightening the four bolts equally, the leak went away. They are a bit hard to get to, patience is your friend. Taking the skid plate off will also help. The air seemed to be coming from the actual fitting the copper line went into, but it was really the flange leaking that made it seem that way. One other thing to check are the drain valves on the tanks. Mine were leaking slightly. After fixing those 2 things on my truck, she will hold 60-90psi overnight no problem.

- Taken from Racky on SS: Check air compressor belt condition and tension. If all is good take the black cap off the regulator and you will see a screw with a lock nut. Loosen lock nut and turn screw in 1/8th turn if pressure doesn't come up it could either be a partially clogged air screen on the regulator, a faulty regulator or a compressor on its way out. The truck should hold air overnight.

- Taken from Barrman on SS: The air compressor has something called "unloader valves." The air from the regulator on the firewall opens these valves and makes the compressor not compress. When the regulator decides the system needs more air, it removes the air from the valves and the compressor starts pumping again. Start simple when troubleshooting: Remove the intake screen/filter on the compressor and make sure it isn't plugged up. Still no workie, then start looking at the unloader valves. They are basically held down by a spring. Pull the cover off and check out the springs. My Gasser had one of the two springs broken off just a little at the end of the coil. I put a washer in as a shim and have had 110 psi air ever since. If the unloaders check out ok, then you need to start thinking about rings. However, first pull the output line from the compressor, fire up the truck and see if it is pumping air now. You could have a plugged up line somewhere between the compressor and the tanks. No air out means no air in.

- Taken from Barrman on SS: Another way to keep air in the system without running the engine is to use the emergency glad hand on the passenger side rear. Put fittings on it so you plug an air hose from your home compressor to the glad hand, open the valve and crawl under the truck to find the leak.

- The air compressor is lubricated with engine oil. There are oil galleys on the compressor and the engine and pressurized oil from the pump is sent to the compressor and out of it back to the sump.

- The air system check valve is the big round thing in the line that connects your two tanks together.

Brake System

- 2 Quarts DOT 3 AND DOT 5 Brake Fluid

Brake System Notes:

- Check Master Cylinder Fluid Level and top off brake fluid if necessary

- Open the little plate on the driver side floor board and you will see the cap and the breather line on the brake system

- When mixed dot5 and dot3 make a thick goo at the bottom of the Master Cylinder. It will clog the lines and destroy the seals on the wheel cylinders if it makes it that far. Silicone is purple (at least the new stuff is) if you put some of the fluid in question in a jar with a few drops of water and shake it up a lot, dot5 will not mix with the water. Dot3 will.

- DOT 3, 4, and 5.1 can be mixed if necessary, according to the instructions on the cans. DOT 5 and DOT 5.1 are not the same. DOT 5 is a silicone based fluid, and DOT 3, 4, and 5.1 are glycol based. There are two types. The first one is regular auto brake fluid. The second type is Silicone-based brake fluid. You can not mix the two types of fluid (well, you can, but you will end up with a jelly-like mess). You need to find out which you have already in the system. Here's how:

1. Get a dropper (an eye or ear-dropper) and withdraw some fluid from the master cylinder.

2. Put it into a glass jar and then add some clean water to the fluid.

3. Now put the lid on the jar and shake it well.

4. Let it stand for a few minutes.

5. If the water and the fluid have mixed thoroughly and can not be separately identified, then you have regular auto brake fluid.

6. However, if the water and the fluid have not mixed, or have formed blobs or layers, then the fluid is Silicone.

Electrical System

- Two Optima Yellow Top Batteries

- Battery Terminals

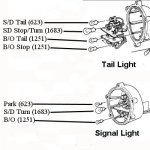

- Napa Light Bulbs (Front & Rear Parking # 623, Turn # 1683, Headlight # 4863, Instrument # 1829)

Fuel System

- 10 Gallons of Premium Diesel Fuel

- Diesel 911 or Diesel Kleen Fuel Additive

- Fuel Filters (Primary Napa # 3511, (2 total) Secondary Napa # 3540 Gold)

- Fuel Filter Gasket (Primary Napa # 5131 Secondary # 5070)

- Piece of wood to place in front of air intake in case of a runaway motor

Fuel System Notes:

-Line Cleaning: 1) Remove fuel line from tank 2) Open water separator 3) Remove secondary and final filter, clean bosses 4) Blow fuel line back towards tank 5) Re-Install fuel line

- If it is a multi-fuel there is a bleeder nut on top of the secondary and final fuel filter assembly to help bleed the system. It is on the left side of the engine near the firewall. Since it has a tank pump, the fuel will go from the tank and flow through the primary, secondary and then final fuel filter. Do this with the master switch on. When you see fuel coming out of the bleeder system, it is bled up to that point. Retighten bleeder screw. Go back and hold throttle wide open and crank. The cylinders will fire one to two at a time. Back off throttle a little at a time till vehicle smooths out. Avoid revving engine past 1000rpms. After a couple minutes of idling it should be OK. Be ready with a piece of wood to place in front of air intake (to cut-off air supply and emergency stop engine) in case of a runaway motor.

- The fuel line comes up at the fuel filter closest to the firewall. One can gain easy access to it from topside.

- The primary fuel filter is also a water separator. The primary filter rides on the spring. The bottom half of the canister is used to catch any water in the system.

- Location: The primary fuel filter (Napa # 3511) is by itself under the alternator. Both secondary (Napa # 3540) are on the driver's side of the motor block behind the oil cooler.

Engine

- Compressor Belt - (Napa # 25-9510, Good Year # 17511, Gates # 9510)

- Alternator Belt (2 needed) - (Napa # 25-9470)

- Auto clutch return springs ( in case throttle linkage is loose)

Engine Notes:

- There are only 3 belts on the M35A2. One for the air compressor and two (a matched set) for the generator.

Tools/Items To Bring

- Air Compressor

- Air Pressure Gauge

- Air nozzle with tube attachment and tire inflator

- Complete Mechanics Socket and Rachet Set

- Allen Wrenches (9/16 for transfer case)

- Various hand tools

- Generator

- Various funnels

- 2" Pipe Wrench

- Rags/Paper Towels

- Tow Bar

I find that there is a lot of information on these forums but that even with using the Search function, everything is scattered and relatively had to find. What I would like to is kind of organize some general information for not only myself, but for others as well. I think that it would be a great learning experience for me, we would all come up with a nice printable PDF (that I would make) and it would cut down on some of the newbie posts.

The first list I would like to start on is a Recovery manual that states what to bring (ie. items on the great list) and how much/how to get the vehicle ready for recovery. I would like to include in each category what type of fluid/lubrication to use and how much is needed. When everyone says top off all fluids, which fluids and where. Here are the topics I would like to cover:

- Engine Oil

- Transmission

- Axles

- Air System

- Differentials

- Brakes

- Transfer Case

- Stearing Gear

Side Notes for:

- Oil Filter

- Fuel Filter

- Fuel Additives

- Oil Additives (Diesel Kleen/Diesel 911)

What do you all think? I'd like to include pictures as well for a "Recovery for Dummies" manual. Cheers!

** I've edited the original post and am placing the work in progress here. Edits, additions and modifications will be made frequently and when needed:

Oil/Engine Lubrication

- 1 Case of 15/40 Engine Oil

- Slick 50 Turbo Formula

- 5 Gallon Pale of GL-1 or GL-5 Gear Oil good for Yellow Metal (Napa # SUS52)

- Engine Oil Filter (Napa # 1133)

- Oil Filter Gasket (Napa # 5119)

- Grease gun for chasis lub with extra tubes

- Pump for GL-1 Gear Oil

**For Synthetic use**

- **Amsoil 15w40 Diesel Marine Oil**

- **Amsoil 80w90 diff oil (reg) for diffs, transmission and transfer case**

- **Amsoil Synthetic Grease**

Lubrication Notes:

- Add Slick 50 to oil before cranking to aid turbo lubrication

- Check Transmission Oil - When filling the transmission with the side plug, fill until the fluid goes to the first knuckle on your index finger. Don't actually fill-to-spill or it will be slightly over-serviced.

- Check Transfer Case Oil - Knuckle fill appropriately with GL-1

- Check Differential Oil - Knuckle fill appropriately with GL-1

- Drain and refill transmission, differentials and transfer case as soon as recovery is complete

Cooling System:

- 2 Gallons Anti-Freeze

- Distilled Water

- Radiator Cap (Napa # 703-1422)

- Thermostat (Multi-fuel Napa # 358-180)

Air System

- Air Filter (Napa # 2837)

- Alcohol/Methanol

Air System Notes:

- Open air tanks and remove water and crud from system.

- Air Compressors: One is a single cylinder, the round one (Midland). The other is a two cylinder that looks like a figure 8 (Bendix). Both are air cooled.

- Taken from Cleb on SS: On the airpack, frame side, there is an airline coming in, that goes to a flange, which is held to the airpack by 4 bolts. I had a slight air leak I could feel around that area (only held about 60psi running). After tightening the four bolts equally, the leak went away. They are a bit hard to get to, patience is your friend. Taking the skid plate off will also help. The air seemed to be coming from the actual fitting the copper line went into, but it was really the flange leaking that made it seem that way. One other thing to check are the drain valves on the tanks. Mine were leaking slightly. After fixing those 2 things on my truck, she will hold 60-90psi overnight no problem.

- Taken from Racky on SS: Check air compressor belt condition and tension. If all is good take the black cap off the regulator and you will see a screw with a lock nut. Loosen lock nut and turn screw in 1/8th turn if pressure doesn't come up it could either be a partially clogged air screen on the regulator, a faulty regulator or a compressor on its way out. The truck should hold air overnight.

- Taken from Barrman on SS: The air compressor has something called "unloader valves." The air from the regulator on the firewall opens these valves and makes the compressor not compress. When the regulator decides the system needs more air, it removes the air from the valves and the compressor starts pumping again. Start simple when troubleshooting: Remove the intake screen/filter on the compressor and make sure it isn't plugged up. Still no workie, then start looking at the unloader valves. They are basically held down by a spring. Pull the cover off and check out the springs. My Gasser had one of the two springs broken off just a little at the end of the coil. I put a washer in as a shim and have had 110 psi air ever since. If the unloaders check out ok, then you need to start thinking about rings. However, first pull the output line from the compressor, fire up the truck and see if it is pumping air now. You could have a plugged up line somewhere between the compressor and the tanks. No air out means no air in.

- Taken from Barrman on SS: Another way to keep air in the system without running the engine is to use the emergency glad hand on the passenger side rear. Put fittings on it so you plug an air hose from your home compressor to the glad hand, open the valve and crawl under the truck to find the leak.

- The air compressor is lubricated with engine oil. There are oil galleys on the compressor and the engine and pressurized oil from the pump is sent to the compressor and out of it back to the sump.

- The air system check valve is the big round thing in the line that connects your two tanks together.

Brake System

- 2 Quarts DOT 3 AND DOT 5 Brake Fluid

Brake System Notes:

- Check Master Cylinder Fluid Level and top off brake fluid if necessary

- Open the little plate on the driver side floor board and you will see the cap and the breather line on the brake system

- When mixed dot5 and dot3 make a thick goo at the bottom of the Master Cylinder. It will clog the lines and destroy the seals on the wheel cylinders if it makes it that far. Silicone is purple (at least the new stuff is) if you put some of the fluid in question in a jar with a few drops of water and shake it up a lot, dot5 will not mix with the water. Dot3 will.

- DOT 3, 4, and 5.1 can be mixed if necessary, according to the instructions on the cans. DOT 5 and DOT 5.1 are not the same. DOT 5 is a silicone based fluid, and DOT 3, 4, and 5.1 are glycol based. There are two types. The first one is regular auto brake fluid. The second type is Silicone-based brake fluid. You can not mix the two types of fluid (well, you can, but you will end up with a jelly-like mess). You need to find out which you have already in the system. Here's how:

1. Get a dropper (an eye or ear-dropper) and withdraw some fluid from the master cylinder.

2. Put it into a glass jar and then add some clean water to the fluid.

3. Now put the lid on the jar and shake it well.

4. Let it stand for a few minutes.

5. If the water and the fluid have mixed thoroughly and can not be separately identified, then you have regular auto brake fluid.

6. However, if the water and the fluid have not mixed, or have formed blobs or layers, then the fluid is Silicone.

Electrical System

- Two Optima Yellow Top Batteries

- Battery Terminals

- Napa Light Bulbs (Front & Rear Parking # 623, Turn # 1683, Headlight # 4863, Instrument # 1829)

Fuel System

- 10 Gallons of Premium Diesel Fuel

- Diesel 911 or Diesel Kleen Fuel Additive

- Fuel Filters (Primary Napa # 3511, (2 total) Secondary Napa # 3540 Gold)

- Fuel Filter Gasket (Primary Napa # 5131 Secondary # 5070)

- Piece of wood to place in front of air intake in case of a runaway motor

Fuel System Notes:

-Line Cleaning: 1) Remove fuel line from tank 2) Open water separator 3) Remove secondary and final filter, clean bosses 4) Blow fuel line back towards tank 5) Re-Install fuel line

- If it is a multi-fuel there is a bleeder nut on top of the secondary and final fuel filter assembly to help bleed the system. It is on the left side of the engine near the firewall. Since it has a tank pump, the fuel will go from the tank and flow through the primary, secondary and then final fuel filter. Do this with the master switch on. When you see fuel coming out of the bleeder system, it is bled up to that point. Retighten bleeder screw. Go back and hold throttle wide open and crank. The cylinders will fire one to two at a time. Back off throttle a little at a time till vehicle smooths out. Avoid revving engine past 1000rpms. After a couple minutes of idling it should be OK. Be ready with a piece of wood to place in front of air intake (to cut-off air supply and emergency stop engine) in case of a runaway motor.

- The fuel line comes up at the fuel filter closest to the firewall. One can gain easy access to it from topside.

- The primary fuel filter is also a water separator. The primary filter rides on the spring. The bottom half of the canister is used to catch any water in the system.

- Location: The primary fuel filter (Napa # 3511) is by itself under the alternator. Both secondary (Napa # 3540) are on the driver's side of the motor block behind the oil cooler.

Engine

- Compressor Belt - (Napa # 25-9510, Good Year # 17511, Gates # 9510)

- Alternator Belt (2 needed) - (Napa # 25-9470)

- Auto clutch return springs ( in case throttle linkage is loose)

Engine Notes:

- There are only 3 belts on the M35A2. One for the air compressor and two (a matched set) for the generator.

Tools/Items To Bring

- Air Compressor

- Air Pressure Gauge

- Air nozzle with tube attachment and tire inflator

- Complete Mechanics Socket and Rachet Set

- Allen Wrenches (9/16 for transfer case)

- Various hand tools

- Generator

- Various funnels

- 2" Pipe Wrench

- Rags/Paper Towels

- Tow Bar

Last edited: