RE: Re: RE: Ok then...

Today I was in Elkhart, IN. I stopped by Gillette Generators and asked them to have a look. Talk about service! They sent the Tech support guy and also the fuel system technician out into the parking lot to check it. Sure enough, the speed was within parameters, but the voltage was low. It turned out to be the capacitor, a 50uF 330VAC unit.

This capacitor is part of the exciter and regulator circuit. There is no solid state regulator needed on this model. (A plus as far as I am concerned on a smaller unit, to have less complex mechanisms). So, the capacitor was replaced with a new type they have recently started using, 50uF/440VAC. Interestingly, both brands of capacitor are from very reputable American makers. In any case, I just had a bad capacitor, infant mortality. It must have died during the 100 degree day when I had the 3KW load for 8 hours.. It should not have, but again, just a bad cap, could happen to anyone.

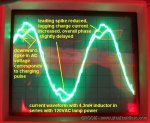

The owner came out and greeted me personally, and was very helpful during the tests -he is the real scientist behind the design of the alternators, and I do mean science. Everything he showed me bespoke years of experience and hands-on research resulting in continuous improvement. We tested the set extensively as I added more and more load and when I had the load balanced and maxed out (about 3300 watts is all I can draw with the shelter), they set the voltage to 120V. No load it is 125VAC, full load (which I probably will never see) I expect 115VAC. This is excellent!

While I was there, I also bought an extension for the start/stop control and an oil drain adapter. They gave me a free service manual for the alternator (maybe because I had gone into enough detail regarding the symptoms? -well I am very glad to have it, I enjoyed reading it actually. Before I left, I was also given a spare capacitor, just in case there was any sort of trouble again. Right now, I doubt I will need to use it, but it's good to have on hand when going into the field.

The owner gave me a tour of the facility. I am impressed how modern and automated it is. The metals of the laminations for both stator and rotor are specially treated, but in different methods. The stator of the generator set is made of a special steel alloy designed to remain magnetized, so no exciter re-charge is ever needed. The rotors are specially shaped and have a pitch to reduce harmonics and make cleaner power, and are also fitted with special damping bars to direct the flux lines accurately to the correct poles as the machine rotates. There are some details/techniques I was not shown but none of it is magic, just hard physics. All of the copper is 100% pure copper, not alloys like some units use -and these sets have -alot- of copper in them for their KW rating. I suppose that is why it starts my big air conditioner so easily. The ends of the windings where they come together electrically are ultrasonically welded, not crimped as with many competitors (I know because I have taken many sets apart to rewire or fix them). The weld can be seen to be a real weld, not just a hard contact that was crimped. All of the operations are done with precision special machines so there is no chance of nicking the wire windings as they are inserted into the stator The insulating material between the windings and the stator is an impregnated-like glass-mylar-glass material, very nice! Besides the various tests along the way for QA, each completed unit is 100% tested for frequency power and voltage before shipping. The whole operation is high tech, pretty clean environmentally, and employs American people to make the machines there in Indiana. Before I get accused of giving an ad for Gillette, all I have said is just the facts, and you know me, if the thing blows up tomorrow or next week, you'll hear about it.