Skrilex

Banned

- 355

- 2

- 0

- Location

- Portland Oregon

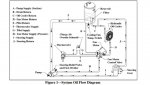

New to these systems and I’m wanting to find a way to have hydraulic pressure from the system without messing up the hydroboost. My pump is a higher flow type ZF although I don’t have solid numbers. I want to explore the hydraulic fan idea.

does the system work on constant pressure or does it somehow demand pressure only when needed and bypass? Is the steering circuit isolates and could that be tapped for pressure to feed a fan? Or could the pump output be tapped?

does the system work on constant pressure or does it somehow demand pressure only when needed and bypass? Is the steering circuit isolates and could that be tapped for pressure to feed a fan? Or could the pump output be tapped?