I have an 802 and it is not getting fuel to the injectors.

Can someone please help with what I need to do next?

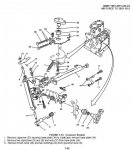

I am getting fuel all the way to that governor shut off that is attached to the high pressure fuel pump.

The part that kills the fuel to the diesel engine.

I have fuel going into that governor part but no fuel coming out of the pressure pump and going to the injectors.

The arm on the governor does turn back and forth and I didn't notice weird about it.

The electric arm that controls the engine shut off that is attached to the governor is function as it should, and when you go to start it, the arm pulls back it free up the governor. The when you turn it off it swings back and shut the governor.

I picked up this MEP 802A with 12 hours on it. This is not a rebuild it has only 12 hours.

When I got it it was missing the oil filter and the main breaker behind the instrument panel was popped.

I add oil, anti freeze, oil filter, fuel and reset the breaker behind the panel.

It turn over but will not start because the injectors are not getting fuel.

Can someone please help with what I need to do next?

I am getting fuel all the way to that governor shut off that is attached to the high pressure fuel pump.

The part that kills the fuel to the diesel engine.

I have fuel going into that governor part but no fuel coming out of the pressure pump and going to the injectors.

The arm on the governor does turn back and forth and I didn't notice weird about it.

The electric arm that controls the engine shut off that is attached to the governor is function as it should, and when you go to start it, the arm pulls back it free up the governor. The when you turn it off it swings back and shut the governor.

I picked up this MEP 802A with 12 hours on it. This is not a rebuild it has only 12 hours.

When I got it it was missing the oil filter and the main breaker behind the instrument panel was popped.

I add oil, anti freeze, oil filter, fuel and reset the breaker behind the panel.

It turn over but will not start because the injectors are not getting fuel.

Attachments

-

74.8 KB Views: 34