-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

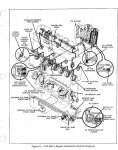

LDT 465 Multifuel. Andy3's Broken Camshaft

- Thread starter oddshot

- Start date

More options

Who Replied?- 26,246

- 1,185

- 113

- Location

- NY

And interestingly, the camshaft bearings are not all the same.

Each has it's own part number.

BEARING,SLEEVE:CAMSHAFT REAR 10910980 (19207) EA 1 SEE SET 17 1

3120-849-1030

KF H ZZ BEARING, SLEEVE:CAMSHAFT REAR INTERMEDIATE EA 1 SEE SET 17 2

10910979 (19207) 3120-849-1030

KF H ZZ BEARING,SLEEVE:CAMSHAFT FRONT INTERMEDIATE EA 1 SEE SET 17 3

10910978 (19207) 3120-849-1030

KF H ZZ BEARING,SLEEVE:CAMSHAFT FRONT 10910977 (19207)

Each has it's own part number.

BEARING,SLEEVE:CAMSHAFT REAR 10910980 (19207) EA 1 SEE SET 17 1

3120-849-1030

KF H ZZ BEARING, SLEEVE:CAMSHAFT REAR INTERMEDIATE EA 1 SEE SET 17 2

10910979 (19207) 3120-849-1030

KF H ZZ BEARING,SLEEVE:CAMSHAFT FRONT INTERMEDIATE EA 1 SEE SET 17 3

10910978 (19207) 3120-849-1030

KF H ZZ BEARING,SLEEVE:CAMSHAFT FRONT 10910977 (19207)

- 26,246

- 1,185

- 113

- Location

- NY

Also notable is the fact that the parts listing says that there is a replacement camshaft and gear that replaces an earlier part number.

CAMSHAFT,ENGINE REPLACES OLD 1

CAMSHAFT AND GEAR

And, it's made by Hercules. http://www.parttarget.com/2815-00-808-6978_2815008086978_10951216.html

CAMSHAFT,ENGINE REPLACES OLD 1

CAMSHAFT AND GEAR

And, it's made by Hercules. http://www.parttarget.com/2815-00-808-6978_2815008086978_10951216.html

Last edited:

gimpyrobb

dumpsterlandingfromorbit!

- 27,786

- 769

- 113

- Location

- Cincy Ohio

Does the first cam bearing share its oil with the air compressor? Maybe a point of low pressure over it's lifetime means it wears faster?

- 26,246

- 1,185

- 113

- Location

- NY

It shares a connection with the IP.

Perhaps a fuel diluted oil supply(from the HH or orings) could cause wear on that bearing, allowing accelerated wear.

Maybe the original cams had a failure issue, and that is all it is.

I doubt we will ever know for sure.

Perhaps a fuel diluted oil supply(from the HH or orings) could cause wear on that bearing, allowing accelerated wear.

Maybe the original cams had a failure issue, and that is all it is.

I doubt we will ever know for sure.

gimpyrobb

dumpsterlandingfromorbit!

- 27,786

- 769

- 113

- Location

- Cincy Ohio

Pretty sure the IP's oil dumps out the front of the unit, behind the gear. I don't think fuel diluted oil would be an issue.

- 26,246

- 1,185

- 113

- Location

- NY

Both the air compressor and the IP get oil from the front cam bearing source.

When the truck is shutdown, the oil (contaminated) could drain back and "wash" or contaminate that bearing.

Just a possibility.

When the truck is shutdown, the oil (contaminated) could drain back and "wash" or contaminate that bearing.

Just a possibility.

- 34,010

- 1,821

- 113

- Location

- GA Mountains

Since we are going in this direction, there are times when the compressor gasket is made in the field and the oil hole is overlooked. This usually results in a compressor failure but I wonder if the resultant issue factors in with the cam issue.

- 3,871

- 499

- 83

- Location

- Gray Court SC

I believe we're starting to over think this.

The best clue is the fact that Doghead found that they found a problem with the cam's and got a replacement from Hercules.

That is a huge clue.

The best clue is the fact that Doghead found that they found a problem with the cam's and got a replacement from Hercules.

That is a huge clue.

oddshot

Active member

- 781

- 120

- 43

- Location

- Jasper, Georgia

This is consistent with the information found in the TM.And interestingly, the camshaft bearings are not all the same.

Each has it's own part number.

The bearings are all different size bigger in the front, smaller in the rear. I have seen this before on other inline engines of what might be called "older" design and assumed, although never asked that it might have something to do either with ease of assembly OR a slightly diminished oil pressure front to back, i.e., from first fed to last fed.

It makes more work for me when I turn this broken camshaft into a tool (driver) for installing the bearings. Hopefully, I will be able to adapt this tool into something that will be useful in REMOVING the bearings. But that would depend on how the last bearing is held in the block.

For those following along at home, the TM's I have been using can be found and downloaded here:

http://www.jatonkam35s.com/DeuceTechnicalManuals/LD-465Maint.Man.TM9-2815-210-34-2-1.pdf

http://www.jatonkam35s.com/DeuceTechnicalManuals/LD-465Maint.Man.TM9-2815-210-34-2-2.pdf

... with a tip of the hat to Jatonka

oddshot

Active member

- 781

- 120

- 43

- Location

- Jasper, Georgia

I'm seeing it the other way around. Although the area behind the first bearing was perfect for this type of damage, I don't think the cam would have broken if the bearing weren't so baddly worn. The TM indicates the bearing was way beyond the wear limit.Maybe the original cams had a failure issue, and that is all it is.

Sometime this weekend I should be able to remove the cam and measure the rest of the bearings.

Yep.I doubt we will ever know for sure.

I do appreciate the diagram. Thank you for finding it for me.

- 3,871

- 499

- 83

- Location

- Gray Court SC

OK question could the cam just like a drive shaft become unbalanced and cause wear on bearing with the gear on that end .

If all the other bearings are in tolerance

If all the other bearings are in tolerance

steelypip

Active member

- 769

- 68

- 28

- Location

- Charlottesville, VA

This failure mode is familiar to me. I've seen other gear-drive cam engines develop issues from the drive-end bearing going large. Usually the dissimilar materials in the cam drive result in stripped cam gear teeth as the cam gear walks out of accurate mesh with the crank gear. On a longer engine with lots of cam bearings and a harder cam, like this one, I can certainly believe that excessive drive end bearing radial play resulted in a cyclic stress fracture of the cam.

All the cams I've ever seen that axially slipped into a block had different diameter bearings with the smallest at the back and the largest at the front. This was specifically to ease installation of the cam and prevent scuffing the bearings on installation. Lots of Detroit pushrod car engines used this system, and I think some still do.

The fact that the bearing with the excessive radial runout is both the one under the highest radial load and is also the one that gives up some of its oil feed to the compressor and IP is suggestive as well. That's one bearing you'd want to be on the tight end of the clearance range when building the engine. If we then assume that all the other cam journals slid past it on the way into the block, well, it's not too hard to postulate an axial score or scrape of the bearing costing a critical amount of oil cushion.

Lots of possibly contributory stuff. I don't think you're going to find a single golden BB.

All the cams I've ever seen that axially slipped into a block had different diameter bearings with the smallest at the back and the largest at the front. This was specifically to ease installation of the cam and prevent scuffing the bearings on installation. Lots of Detroit pushrod car engines used this system, and I think some still do.

The fact that the bearing with the excessive radial runout is both the one under the highest radial load and is also the one that gives up some of its oil feed to the compressor and IP is suggestive as well. That's one bearing you'd want to be on the tight end of the clearance range when building the engine. If we then assume that all the other cam journals slid past it on the way into the block, well, it's not too hard to postulate an axial score or scrape of the bearing costing a critical amount of oil cushion.

Lots of possibly contributory stuff. I don't think you're going to find a single golden BB.

o1951

Active member

- 899

- 155

- 43

- Location

- Bergen County, NJ

To put it simply, with a gear drive, there is a force trying to push the gears apart that is countered by the upper part of the cam bearing. This force adds to the force created by the cams pushing on the tappets. The force on a gear drive is the opposite of a chain drive.OK question could the cam just like a drive shaft become unbalanced and cause wear on bearing with the gear on that end .

If all the other bearings are in tolerance

What they are now thinking is that the bearing may have worn so much that the camshaft was bending, and that caused the failure. Sorta like rolling a pencil on your desk - no bending. Then you wind tape on one end and force the pencil to stay flat on the desk. After a time, the constant bending cause the pencil to break someplace near the tape.

I hope that gives you a picture of the issue.

From experience working on engines, the bearing appears to have sufficient surface area, however, calculating the component forces on the bearing is a bit above my pay grade. It seems that on this engine, the oil gallery that feeds the #1 cam bearing also feeds the compressor and IP. This complicates lubrication.

A camshaft does not become unbalanced in operation. To be unbalanced, something has to break, and the engine stops.

A drive shaft is different - it has universal joints, which can cause unbalance when worn because the shaft is no longer centered when in operation, and it can be bent when driving over objects that it contacts, or by a GL forklift contacting it when the truck is moved. It may still operate, but like you inferred, the vibration can damage trans and diff bearings.

Last edited:

bchauvette

New member

- 807

- 5

- 0

- Location

- Easley SC USA, 29640

Is it possible to do an "in frame" cam replacement?

- 3,871

- 499

- 83

- Location

- Gray Court SC

Butch I would say yes. Once you get the radiator and front end off.

oddshot

Active member

- 781

- 120

- 43

- Location

- Jasper, Georgia

The better question is ... Is it possible to do an "in-frame" cam BEARING replacement .... perhaps as a PM BEFORE the cam breaks.Is it possible to do an "in frame" cam replacement?

That would depend on how easy the last bearing comes out ... and that is another thing I'm looking at.

- 12,195

- 327

- 0

- Location

- gainesville, ga.

I believe the hole in the block behind the last cam bearing is closed by a freeze plug, this would make it hard to pull the bearing.

I used to use the stepped cam bearing install tool to pull the bearing by placing the correct install step BEHIND the bearing to pull it out, If you have the correct cam bearing stepped install driver, it is a piece of cake to pull them.

I used to use the stepped cam bearing install tool to pull the bearing by placing the correct install step BEHIND the bearing to pull it out, If you have the correct cam bearing stepped install driver, it is a piece of cake to pull them.

bchauvette

New member

- 807

- 5

- 0

- Location

- Easley SC USA, 29640

Replacing freeze plugs are no big deal IF you can get to them. Would an access hole in the fire wall be in order?The better question is ... Is it possible to do an "in-frame" cam BEARING replacement .... perhaps as a PM BEFORE the cam breaks.

That would depend on how easy the last bearing comes out ... and that is another thing I'm looking at.

- 112,569members

- 166,174threads

- 2,340,516posts

- 764online users