Ronmar

Well-known member

- 4,136

- 7,946

- 113

- Location

- Port angeles wa

Does your ex brake disengage when you step on tbe brake pedal?

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

It does not, but it can. The issue is on the earlier A0 with the WTEC 2 transmission, the transmission auxiliary function used for ex brake is already assigned/wired and most likely the TCU is programmed for PTO function. I have not confirmed that PTO programming on mine, but I have confirmed that it is NOT programmed for ex brake control, as it does not energize the proper output signal when the ex brake signal is applied.Question: does M1078 A0 have or can have exhaust break?

Question: does M1078 A0 have or can have exhaust break?

And his was the A0 with a WTEC 3 that was already configured for the ex brake…I think Sean Filler did one on his truck which if I remember correctly was an A0. He did videos on the install

(45) Abel LMTV build part 112 (Pacbrake PXRB CAT 3116 mechanical install) - YouTube

This right here. Mine is a 98 with the WTEC 2…Does your shift selector window have one or two dispays? Here are examples of each one. Mine is a 98 and it has WEC III

WTEC II Transmission ECU / Shifter Control Assembly for M1078 2 ½ Ton Trucks, M1083 5-Ton Trucks (easternsurplus.net)

Allison Transmission Shift Selector 29538360 WTECH III for sale online | eBay

I would call PAC brake and see what their latest kit is, but It has been covered in one of Sean's video's about 4 years ago:My truck is a 98 A0 with WTEC 3. What exactly would be involved in adding an exhaust, or a PAC brake? Assuming the WTEC 3 is already configured.

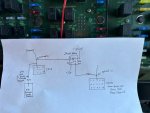

Basically accessing the vehicle interconnect wiring similar to what is seen in this WTEC2 diagram. Pacbrake would have the exact wiring config. I saw it not long ago, let me see if i can find a link. This diagram shows using a VIM relay, and you don't have a VIM, so you will need to add a relay…My truck is a 98 A0 with WTEC 3. What exactly would be involved in adding an exhaust, or a PAC brake? Assuming the WTEC 3 is already configured.

So our 3116 is Full Marmon ? which PRBX model did you get? Understanding I got from PacBrake tech was that the PRBX workings is most about the balance dance between spring, orifice size and check valve matching the engine's exhaust pressures... Then of course the way it mounts and exhaust size. (ours is 4"?)I just procured a PRXB4, so looks like I will be working this out on my WTEC2

side note.... cause of pacbrake not partnering as nice with the programming in the Wtech II on FMTV's.... one thought have had was to move the whole shifter/keypad to an armrest built onto the dog house .... kinda create a Star Trek Captains chair (just aged myself) with the shift pad right in reach instead of up on dash. That way one can get full use of the PacBrake since it looks like our programming wont down shift her. Problem solved.. just flick open a clear cover made to sit on the keypad and down shift yourself. No need to unbuckle seat belt to reach the dash corner to do that.So our 3116 is Full Marmon ? which PRBX model did you get? Understanding I got from PacBrake tech was that the PRBX workings is most about the balance dance between spring, orifice size and check valve matching the engine's exhaust pressures... Then of course the way it mounts and exhaust size. (ours is 4"?)