- 2,661

- 2,194

- 113

- Location

- Sunman Indiana

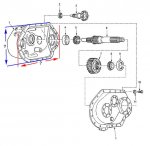

I've seen a few pictures scattered around and I know it's been talked about before, looking for pictures to see if theres a typical break pattern that may be able to be reinforced, or to assess the difficulty of making a stronger case, especially when all the spares dry up.

Also if you could post what events caused the failure.

Also if you could post what events caused the failure.