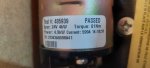

just thought I would post something I found today that was interesting to me at least. I might have found the issue with my temperature light. I pulled out the temperature sensor / sending unit and found that it was not the same as the TS81 that I replaced it with. I didn't think to get a photo of both of them side by side before I installed the new one. But I've got a photo of the old one I pulled out, and a screen shot of the TS81 from Oreillys.

I had searched the TM for the Temp Sensor part number, which gave a GM number. Then I took the GM # and ran a search here on SS in the CUCV forum, and found that the replacement would be the

TS81. Does this sound right??

Both are the same thread size and thread pitch and single blade connector. But are made different. Maybe just a different brand? Old design??

In any case, hope this fixes my temp light "glowing" immediately at cold start, and full brightness when engine is warm.

Also replaced the coolant level sensor, hope that stops the light from 'blinking' on and off sometimes and etc.

And I upgraded the thermostat from a

180f to the correct

Murray 42995. Which by the way, was supposed to be

(and is listed as being) a

195F, but on the thermostat itself it shows

88 Celsius, which converting to Fahrenheit would be

190F. Only 5 degrees, but it makes this thermostat only

10 degrees hotter than the 180F that was in it. I doubt it would matter, guess I'm just nitpicking.

I have some work on the battery cables to finish before I can try to start the truck, had a little corrosion trying to start in the wires before it went into the copper connectors. So I cut off the ends to get back to clean wire and redoing them. Should get that done tomorrow unless something comes up.

Hopefully the truck starts without issue and the starter doesn't need shims. If it does, then I think I'll try your method

87cr250r first, to measure the pinion gear and ring gear gap. I can remove the battery cable and just make a jumper wire to click the solenoid in like you were talking about. Of course I can only hold the solenoid on for a few seconds at a time, don't want to overheat it or anything.

If for some reason that doesn't work, then I guess I'll have to remove the starter and do it by hand like you said

Barrman. But I really don't want to remove the starter again if I can keep from it...

In either case, if shims are needed I'll probably have to go buy a pack, as I may have a couple but not sure what thickness I may end up needing. Been a long time since I've needed any. HOPE I don't need them now.