- 2,104

- 669

- 113

- Location

- Orlando, FL

Remove the nylon screw from the alternator with the Transpo regulator. I'm pretty sure that regulator is adjustable.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

The fat wire in the bottom corner is the positive output of the alternator, which goes to the negative post on the back battery, which connects to the positive post of the front battery. (They were out of red 2G wire.) The upper fat wire goes to ground, though it's not fat enough yet.I might be missing something here, but it looks like the alternator is grounded to ITSELF, and that doesn't make sense.

It's that smaller wire between the two terminal posts right?

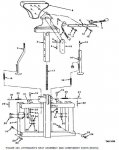

The M1010 has an "Attendant's Seat" in the back. It looks a little like a Harley saddle with a seat belt. It sits on a steel frame that rolls the length of the ambulance, and it's spring loaded to allow the attendant to pop up to deal with the upper litters, or pop down to deal with the lower. Foot pedals control the rolling and the height.

-jpg

I can sure understand how you might want to "deep-six" the seat (considering that you're not operating as an active combat ambulance).Well, for what it's worth, after my first camping trip with 2 kids, I promptly removed said seat and stored it away. Always seemed to be in the way. I now keep a couple of pieces of 1x12 to span the area between the seats. Nice seat and step.

With young kids, it surely would be a menace. Lots of sharp corners and pinch hazards. I would remove it too, if I had little ones in the mix.I can sure understand how you might want to "deep-six" the seat (considering that you're not operating as an active combat ambulance).

But I admire it as a GREAT concept, whoever came up with the idea.

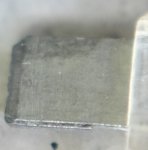

That's a pretty long thread (like about 5-6 pages):Fuse didn't blow. It melted. Before & after picture below.

View attachment 582018

The answer is here:

.

That's a pretty long thread (like about 5-6 pages):

- Do you know what post # the answer was in?

(PS- Yes, I admit to being kind of lazy here).

Please remove all remnants of Negativity in and around the vehicle, and be mindful to accentuate the Positive whenever in the truck's vicinity.I'm digging through threads and wikis looking for other troublesome items I should remove from my truck. All suggestions welcome.

I struck out finding replacement bearings for my attendant's seat. I tried the SS classified and various parts sources. So I soaked them for a day in Naval Jelly. 3 of the 4 came out clean and spinning freely. The fourth wouldn't turn until I used tools on it. Then it broke loose. I had sprayed it with WD40, and I could see rusty lubricant running out as I worked the bearings back and forth. So I cleaned that one as best I could, and put it back in the Naval Jelly. Before and after shots below.

View attachment 582890View attachment 582891

View attachment 582888View attachment 582889

I wouldn't recommend this approach for a critical engine or wheel bearing, but for something that allows a seat to slide, I think these will be fine. I'll paint the outside, grease the bearings, and declare victory.

Those bearings cleaned up nicely. You did a good job there.I struck out finding replacement bearings for my attendant's seat. I tried the SS classified and various parts sources. So I soaked them for a day in Naval Jelly. 3 of the 4 came out clean and spinning freely. The fourth wouldn't turn until I used tools on it. Then it broke loose. I had sprayed it with WD40, and I could see rusty lubricant running out as I worked the bearings back and forth. So I cleaned that one as best I could, and put it back in the Naval Jelly. Before and after shots below.

View attachment 582888.

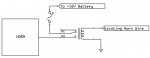

Has someone done a step by step horn relay install for electrical dummies? As Im an electric dummy.Remember that all of the lights go through that fuse as well as the horn power, so that the service/blackout switch can control them at a single point and modifications or additions to the original lighting design has an impact on this one fuse's draw. IMHO this is the one weak point in the entire GM wiring that needs addressing.

The LMC headlight harness, effectively replaced the load of two high wattage headlight fixtures with the miniscule load of a relay coil. I would offer that a similar harness for putting the high current horn load outside the firewall is a good idea.

Modern vehicles have two "fuse panels and relay boxes". The lower power logic loads are handled by the smaller lower power fuse panel and control switches inside the cab, the higher power loads are handled by a larger higher power fuse panel under the hood. This reduces the likelihood that an electrical fire can start inside the cabin since there isn't much energy available inside the cab.

To put a relay on the horn, do this:

View attachment 582422

Those bearings cleaned up nicely. You did a good job there.

I was shopping for some Naval Jelly the other day, and the guy at the store (West Marine) told me it's unavailable now. He said something about the EPA, and how it was not approved for further sale, He had some alternate environmentally-friendly product. And THAT product is probably good enough, but still I asked if he had any old back-stock of the Naval Jelly I could buy, but no dice.

Where did you get your stash!?