Last month I started a few projects on the ambulance, managed to finish one of them and made progress on the others.

The one I finished was replacing the rear marker lights. New sockets and lenses. A simple task by itself but after replacing the sockets I could not get them to work. Long story short, the sockets were not wired as per the diagram, as opposed to being connected to the corresponding turn signal wire (yellow or green) and then to ground, they were connected to the stop/hazard wire (brown) and then to ground, the harness did not look like it had been modified, who knows. I chose to replicate the wiring found on the front marker lights, in order to that, I cut the black wire and connected it to the turn signal wire of the corresponding side. It now lights up with hazard lights, stop lights and turn signal.

Peterson V132R and the electrical diagrams so the above paragraph makes sense.

I also removed the AC unit and have temporarily replaced it with lexan bolted to the body with silicone around the edge to seal up the opening and then a piece of plywood bolted to the outer 4 bolt holes to protect the lexan during driving. Easy enough to remove the plywood when I need a window. I am currently undecided as to what to do there, the AC unit will go into storage.

After ordering and reading Volumes 1 and 2 of the 6.2 Diesel Engine from thedieselpage.com, another project I've started is my own version of Swagner Air, named after Dr. Lee Swagner AKA the clevite kid. The basic concept is help the 6.2 breathe by modifying the air intake and adding a larger exhaust, after having done this, turn up the IP a 1/16th or an 1/8th while monitoring the EGTs.

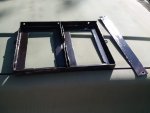

So far I've modified my air intake, by adding 2" inches to its height in order to accept two 3" air filters and opened up to at the inlet to a 4" pipe, Dr. Lee aims his inlet to the front grill, I have a battery tray in the way and I'm not to keen on moving it nor having it get air from there anyway. So, it's currently aimed at the outer fender crumble zone, waiting for a snorkel. Hope the General doesn't mind some Toyota metal underhood. To help support the modified intake I took the rear AC compressor brace off the driver side exhaust manifold and bolted it to the passenger side manifold, then weld a tab to the intake and bolted it to the brace, easily removable.

I'm currently waiting for the machine shop to start/finish? the exhaust flanges, after that I can up the exhaust pipe size to 3" from the manifolds to the exit, install a pyrometer gauge and turn a screw. The screw turning will probably happen after I'm happy with the timing.

Of all the work done this month, the supervisor liked riding in it the most. We put about 200 miles road time this past month, good stuff.

Thanks for reading, good luck folks.

.

.