- 347

- 258

- 63

- Location

- Myakka City, FL

Dear Abbey,

Good Luck is the answer already I know it but I have to attempt this anyhow.

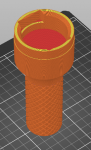

I have need of the Seals on the end of the Cylinders, both expanding and non-expanding type.

Is there a source? Anybody 3D printing them?

Signed, Desperate

Good Luck is the answer already I know it but I have to attempt this anyhow.

I have need of the Seals on the end of the Cylinders, both expanding and non-expanding type.

Is there a source? Anybody 3D printing them?

Signed, Desperate