- 844

- 1,328

- 93

- Location

- La Crosse, WI

Amazing how one little seal can cause so much grief

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

... yup :/Any sign of water at the transfer case drain?

Disappointing to hear but will continue on. It's been 12months since I put fresh oil in it, 8 months since I drove it, and ~3mo since I ran it. I'm also concerned about the torque converter, but hoping that there is some drainback for both C7 and the TC.The glue that binds the clutch media to the discs is water soluble.

I guess it depends upon how long it has been since it was first run and the water mixed/emulsified with the oil. if it has set like that with emmulsified oil for long, the C7 difflock clutch pack may be toast as i believe it is mostly immersed in fluid when not running.

The oil level in the main trans body should be between 1.8" cold and 4" hot above the line where control module bolts to trans housing, so the main clutch disks should only see the emmulsified oil when running...

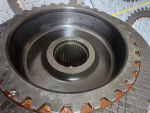

Incoming shortly good sir.thrust bearing pics?

Thrust bearing pictures and also some clutch pack pictures. Not sure how I want to clean those clutches so I haven't yet, just wiped down the reaction plates and set them out.thrust bearing pics?

I can get you better pictures later, but this thing ?Can you shoot a pic of the side of the plate carrier/center component that engages the forward face of the thrust bearing? i am curious what it looks like.

Based on the radically different thickness between the thrust bearing pack and the thrust washer I am thinking that once Allison started seeing the thrust bearing failures they realized they had made a mistake, and that the gap back there probably allows for some acceleration of that heavy center component, perhaps when you release the P6 clutch/shift out of 1st gear, or perhaps when you shift between R and D(Center shaft fore-aft movement from helical gears when P3 bearing carrier reverses directions). The gap left room for acceleration and impact by that heavy center section with the roller thrust-bearing…

Some interesting, uneven, wear scars on the inside of the 2nd gen thrust washer as well.Can you shoot a pic of the side of the plate carrier/center component that engages the forward face of the thrust bearing? i am curious what it looks like.

Based on the radically different thickness between the thrust bearing pack and the thrust washer I am thinking that once Allison started seeing the thrust bearing failures they realized they had made a mistake, and that the gap back there probably allows for some acceleration of that heavy center component, perhaps when you release the P6 clutch/shift out of 1st gear, or perhaps when you shift between R and D(Center shaft fore-aft movement from helical gears when P3 bearing carrier reverses directions). The gap left room for acceleration and impact by that heavy center section with the roller thrust-bearing…

Yep, that thing(splined hub). Looks like a pretty substantial chunk of steel... Idea on how much it weighs?I can get you better pictures later, but this thing ?

View attachment 937879

View attachment 937878

View attachment 937877

Don't have a precise way of weighing it, unfortunately. Utilizing weight comparison, that 5# dumbbell + fat gripz was similar, so I'd guess in the 6-8# range.Yep, that thing(splined hub). Looks like a pretty substantial chunk of steel... Idea on how much it weighs?

Hopefully this transmission thing isn't the end of my story ! I believe I have ordered all the parts needed from my local Allison rep to get it back together, but who knows how long they'll take to get in (one is probably backordered, or something).Subscribing to this. Good idea for paint on the wolverine pump. After my first winter outside, no driving even, it's rusted.

Yessir, planning on pulling the return and letting her pump out as much as she wants.What is "add flush"?

Anecdotal, but my trans had 15w40, I pulled the return line(at trans) and let the truck run till it spit some air. Filled with transynd 668 and ran till red started pushing out the hose. Then reconnected and filled to appropriate level. It worked well for me, although I didn't notice a difference in shifting performance. I mainly did it because it gets cold here and 15w40 is a very poor performer at temps below freezing.

The C7 can, yes.Yessir, planning on pulling the return and letting her pump out as much as she wants.

Flush is someliquified moneyAMSOIL engine+trans flush. I selected it since it's advertised for both engine and trans, and is an EG based product which is hygroscopic/miscible. I'm hoping a combination of those helps clean the forbidden milkshake out of my torque converter... but also fully realize it is semi snake oil to @GeneralDisorder point.

Im trying to dilute the milkshake with the two cheaper T4 changes before Transynd swap. Maybe salvage my C7 clutch pack but the TM seems to indicate it could be swapped while on the truck.