- 2,904

- 1,565

- 113

- Location

- Czech Republic

Actually, I hope I don't have a problem, but cannot get things back together.

About 10 years ago I made this truck into an M51 - M52 switchable dump-tractor truck.

To do so, I disconnected the drive shaft to the pump for the dump hydraulics and also the connections between the controls in the cabin and on the pump. Since then, I did not do anything with that system: the dump was disconnected and the Garwood winch was already kaput.

I now tried to put everything together but cannot connect the rear shifter shaft to the pump. Also, the Dump control lever to raise or lower the dump does not work as should be. Probably it is a question of trying it with the engine on, but I do not want to destroy everything; better ask here first.

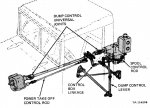

1) The PTO control lever in the cabin has three positions: down-front, up-dump, neutral (which can be locked). This works with the transmission mounted PTO (

a) I cannot really get this lever in the utmost up or down position. Also, when as far up as possible, the rear output shaft to the pump still does not engage with the engine.

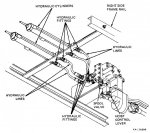

b) The rear shifter shaft does not come backwards enough so I cannot connect the linkage between pump and shifter shaft. Edit to clarify: the shifter shaft comes backwards rotating the next part of the link forward. The link still connected to the pump is also sticking forward. It can move about 1/2 inch forward and backward, but even in the best position, it is still about 1/2 inch further forward than the link to the shifter shaft, so I cannot connect the two.

2) The hydraulic pump is regulated from the control lever in the cabin, inside the cabin to the left behind the driver. This lever should have four positions: Neutral (lever straight up) - down - hold - up. The lever is connected to the pump. I think I get to the hold position, or somewhere between down and hold, but definitely not further down. Does not feel like a stuck spongy feeling but a hard block somewhere.

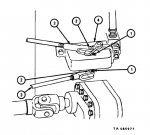

Edit: the rear output shaft from the PTO is connected to the pump and the PTO. I can turn the shaft by hand both directions without problem. Not sure if this is because the pump is in neutral or engaged and rotating without problem.

Any idea?

Starting the engine and with everything in neutral carefully trying to shift the PTO lever?

As said the output shaft is connected to the pump and I can get the dump control lever in neutral, so hopefully trying this with the output shaft connected will not wreck the pump. Or should I disconnect the shaft?

1

About 10 years ago I made this truck into an M51 - M52 switchable dump-tractor truck.

To do so, I disconnected the drive shaft to the pump for the dump hydraulics and also the connections between the controls in the cabin and on the pump. Since then, I did not do anything with that system: the dump was disconnected and the Garwood winch was already kaput.

I now tried to put everything together but cannot connect the rear shifter shaft to the pump. Also, the Dump control lever to raise or lower the dump does not work as should be. Probably it is a question of trying it with the engine on, but I do not want to destroy everything; better ask here first.

1) The PTO control lever in the cabin has three positions: down-front, up-dump, neutral (which can be locked). This works with the transmission mounted PTO (

a) I cannot really get this lever in the utmost up or down position. Also, when as far up as possible, the rear output shaft to the pump still does not engage with the engine.

b) The rear shifter shaft does not come backwards enough so I cannot connect the linkage between pump and shifter shaft. Edit to clarify: the shifter shaft comes backwards rotating the next part of the link forward. The link still connected to the pump is also sticking forward. It can move about 1/2 inch forward and backward, but even in the best position, it is still about 1/2 inch further forward than the link to the shifter shaft, so I cannot connect the two.

2) The hydraulic pump is regulated from the control lever in the cabin, inside the cabin to the left behind the driver. This lever should have four positions: Neutral (lever straight up) - down - hold - up. The lever is connected to the pump. I think I get to the hold position, or somewhere between down and hold, but definitely not further down. Does not feel like a stuck spongy feeling but a hard block somewhere.

Edit: the rear output shaft from the PTO is connected to the pump and the PTO. I can turn the shaft by hand both directions without problem. Not sure if this is because the pump is in neutral or engaged and rotating without problem.

Any idea?

Starting the engine and with everything in neutral carefully trying to shift the PTO lever?

As said the output shaft is connected to the pump and I can get the dump control lever in neutral, so hopefully trying this with the output shaft connected will not wreck the pump. Or should I disconnect the shaft?

1

Last edited:

.jpg)