Hmmm, well auto slacks were a good choice as it looks pretty tight to go in there and adjust periodically with manuals.

I understand what you mean about the drums not covering the shoes completely if mounted outboard. That setup in your pic looks 100% to me like a Dayton drum, which IIRC only measure about 10.6" or so in overall depth.

I was thinking of using a 16.5x8.62 drum as they are 10x11.2 bolt circle, 8.78" pilot and they have a 11.12" depth, which may be enough to cover the shoe. The part number is for that is Gunite Gold 9019X, also crosses to Standard Gunite 3807X, Meritor 53-123581-002, Webb 66854B and Hayes Lemmerz 90486B.

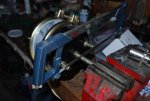

Oh, one more thing. Look at the pushrod to slack relation in that pic. When your park brake is applied the relation should be 90* max, that one is way over and eventually could cause a over-cam situation where the pushrod binds on the slack from the clevis hitting it (very dangerous). Even with a auto slack that can happen. They didn't cut the rod down enough.

Here's Haldex's literature about doing it properly:

http://www.haldex.com/en/north-amer...s_and_Manual_Brake_Adjusters)_L58002_6-07.pdf

One day, with enough research I'm going to find the cure for the outboard drum for this setup. I will share that info with all my brothers & sisters on here when I do.