- 1,962

- 433

- 68

- Location

- Culver City, CA

Preface: I started this project last year in early January. Due to some design changes and funding issues, it is technically not finished yet as of this posting. The last step, making the winch operational again is still in its final stages.

I have researched viable alternatives to the Spicer 6453 5-speed transmission including a different model of the same series, regearing the OEM, a fuller 6-speed (FSO8406A/6406A). I really was not interested in anymore top end speed but was that of better use of each range and less RPM loss between shifts. I decided against all of them for a multitude of reasons and almost just abandoned the thought of ever having a more “drivable” transmission.

I then discovered and researched the Spicer (Tremec/TTC) ESO66-7B 7-speed transmission. The transmission offered closer ratios, a slightly better overdrive (.74 vs .7 , and uses same push-type clutch release fork. It’s spec’d out per TTC for 65,000 lbs. GVW, 185 – 250 hp, 660 lbs./ft of torque which is adequate for an NHC250 equipped M818. See specs under the attached .pdf.

, and uses same push-type clutch release fork. It’s spec’d out per TTC for 65,000 lbs. GVW, 185 – 250 hp, 660 lbs./ft of torque which is adequate for an NHC250 equipped M818. See specs under the attached .pdf.

This install covers an M818 but should be similar to M813 and M814 variants. My truck has modifications, i.e., air brake valves and tubing, that most do not, but I will touch on how I dealt with them. As for other truck variants, the accessory equipment may require additional or alternate modifications. The manual parking brake and all associated parts and hardware will be removed as my truck is now equipped with s-cam spring brakes. I am not making any attempt at modifying that brake system for this project.

Now, for the drawbacks.

I have researched viable alternatives to the Spicer 6453 5-speed transmission including a different model of the same series, regearing the OEM, a fuller 6-speed (FSO8406A/6406A). I really was not interested in anymore top end speed but was that of better use of each range and less RPM loss between shifts. I decided against all of them for a multitude of reasons and almost just abandoned the thought of ever having a more “drivable” transmission.

I then discovered and researched the Spicer (Tremec/TTC) ESO66-7B 7-speed transmission. The transmission offered closer ratios, a slightly better overdrive (.74 vs .7

This install covers an M818 but should be similar to M813 and M814 variants. My truck has modifications, i.e., air brake valves and tubing, that most do not, but I will touch on how I dealt with them. As for other truck variants, the accessory equipment may require additional or alternate modifications. The manual parking brake and all associated parts and hardware will be removed as my truck is now equipped with s-cam spring brakes. I am not making any attempt at modifying that brake system for this project.

Now, for the drawbacks.

- The OEM Spicer is 29.75” in length from clutch hosing versus 36.875” on the 7-speed. This requires rearward movement of the transfer case of at least 7 1/8”, the crossmember just rearward of the transfer case and the transfer case/PTO shift lever trunnion bracket in order to clear the transmission case. The midships driveshaft has to be shortened and the front axle lengthened.

- There is no compatible companion flange for the 7-speed, but there is a half round end yoke. This is not a big deal as it only requires changing the jackshaft’s front u-joint to half round bearing cups only on one axis.

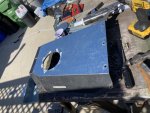

- The shift tower is not forward mounted as it is on the 6453. Some sheet metal work to the front cab tunnel will need to be performed to accommodate the rearward shift tower on the 7-speed.

- The 7-speed has no air poppet valve to select forward or reverse for the transfer sprag. This will be solved with the addition of a 24VDC air directional control valve electrically operated through the transmission reverse switch.

- The stemmed front bearing cover for use with push type clutches is only available for 1 ½” input shafts for this transmission. So, a clutch disc with a 1 ½” hub and a new/modified release bearing assembly is in order.

- The OEM PTO is not compatible with the 7-speed transmission. The drive gears do not match up and the PTO input gear cannot be changed (or at least I was not able to find) to a suitable gear. I have found a compatible alternative that retains the forward/revers mechanical drive feature. However, it does require a two-piece driveshaft to negotiate the distance from the PTO, around the bell housing and to the winch input shaft.

Attachments

-

1.5 MB Views: 11

Last edited: