- 6,862

- 697

- 113

- Location

- Stratford/Connecticut

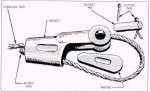

I broke the cable at the end where it meets the hook. It looks like a combination of some of the strands broke and some just pulled out. The truck is a pretty recent rebuild it looks like it wasn't put together properly to begin with. Either way I need to fix it. I found a previous thread discussing the end part but nothing about putting it all back together. Any info or advice would be greatly appreciated.

Will

Will