74M35A2

Well-known member

- 4,145

- 330

- 83

- Location

- Livonia, MI

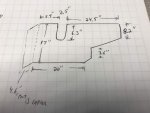

Anybody have the LWS (chicken) shield dimensions and approximate bend angle? Looking to make one vs pay $900. Thanks.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

And postman915, and fuzzy, and tornadogt..... I'll be referencing this thread shortly for mine.Check with Greg 86humv as I believe he sells them and makes reproductions.