KLChurch

New member

- 475

- 2

- 0

- Location

- Montgomery/TX

I'm just wondering. If the transformer gets that hot, why is there not a fan on it? Or is this question a moot point?

Kris

Kris

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Peter,

Here are the measurements you requested:

H1 / H2 1.8 ohm

X1 / X3 .7 ohm

X1 / X2 .4 ohm

X2 / X3 .4 ohm

I measured 588 mA at H1 (never fluctuated)

Let me know if you need anything else.

Brian

Should I go back to the posts and edit that the previous trans I bought is not going to be used?

Or how should I go about it?

Kris

Yes I used it before to edit, but I guess it is only good for that day.

I went to page 10 and the edit tab was not there.

Kris

Some of the reasons that information like what you are after right now was not available, was the trend in the late 70's to not repair things anymore. The A11 was the clasic example. In the early 70's almost all the electrical componets were fixed at the DS, (Direct Support) level. We had at DS level all the test equipment needed to test and repair the A11. And at the end of the day, most repairs were a matter of just replacement of bad componets and then tossing the A11 into a handy gen set to "test" it. We did not have the luxury of time, like here in this thread. And that was the reason things went down hill with fixing things.

When you have to be mission capable, hours count. In the beginning, the NEW mep-004 and 005 and 006 gen sets were far from reliable. And the A11 was one of the worst componets. At one point, our HAWK battalion was non-op, due to so many gen sets having A11 problems. Repair parts were not in the system. People did not know how to test or repair them. The battalion DS was overwhelmed. So the army over reacted. The A11 became a "recoverable item". That ment when it was bad, you ordered a new one and sent the old one back into the supply system, to be sent, (hopefully) to a GS, (General Support) repair facility to be repaired. We still had the capability to repair at battalion level, but the the work went to GS. And they were overwhelmed. Soon more A11's were ordered. Defective A11's and volt reg cards, at some point in time were all shipped to one place in the states, and two places in Germany for repair. They did good work, but fast, hurry, needed were not key words for facilities run by civilians.

The he last few years I was in the army, and all during the time I worked as a contractor, (up to 2010) I only saw brand new A11's being issued. It had become cheaper and easyer to simply procure new ones. I saw piles of them in DRMO scrap piles. This was the beginning of "Pluck and Chuck" repair.

So my A11 was a pluck and chuck? LOL LOL LOLSome of the reasons that information like what you are after right now was not available, was the trend in the late 70's to not repair things anymore. The A11 was the clasic example. In the early 70's almost all the electrical componets were fixed at the DS, (Direct Support) level. We had at DS level all the test equipment needed to test and repair the A11. And at the end of the day, most repairs were a matter of just replacement of bad componets and then tossing the A11 into a handy gen set to "test" it. We did not have the luxury of time, like here in this thread. And that was the reason things went down hill with fixing things.

When you have to be mission capable, hours count. In the beginning, the NEW mep-004 and 005 and 006 gen sets were far from reliable. And the A11 was one of the worst componets. At one point, our HAWK battalion was non-op, due to so many gen sets having A11 problems. Repair parts were not in the system. People did not know how to test or repair them. The battalion DS was overwhelmed. So the army over reacted. The A11 became a "recoverable item". That ment when it was bad, you ordered a new one and sent the old one back into the supply system, to be sent, (hopefully) to a GS, (General Support) repair facility to be repaired. We still had the capability to repair at battalion level, but the the work went to GS. And they were overwhelmed. Soon more A11's were ordered. Defective A11's and volt reg cards, at some point in time were all shipped to one place in the states, and two places in Germany for repair. They did good work, but fast, hurry, needed were not key words for facilities run by civilians.

The he last few years I was in the army, and all during the time I worked as a contractor, (up to 2010) I only saw brand new A11's being issued. It had become cheaper and easyer to simply procure new ones. I saw piles of them in DRMO scrap piles. This was the beginning of "Pluck and Chuck" repair.

The SCR's back then were not that good as the silicone was not up to today's standards.

Like on Brian's VR, this is a classical example of failure, two shortened SCR's and that's not a surprise when you look

at the schematic, as the load is basically comprised of a LCR - with L being T2, C being C2 and then R being R2 and R3....

The SCR’s I ordered are from Vishay #VS-2N689 Mouser #884-2N689 (didn’t see a datasheet)

Interesting you mentioned the problems with the SCR’s.

I bought an NOS VR on EBay a couple years ago. I tried it

shortly after I purchased it. It worked great for about 3 seconds then the generator

shut down with an over voltage condition. I put it away until I had time to deal with it.

I checked it out this morning.

I ran the three tests today and the 2[SUP]nd[/SUP] test failed. I was expecting 48 vdc and got 31.3 vdc.

I used the good VR to test against the bad one. Resistance comparisons loosely pointed to

a bad Q1. I also compared voltages at the junction of R5 / VR1 and R18 / R19. Got

a couple readings that were about 40% to low compared to the working VR. I was suspecting

the SCR’s but hesitated until I saw your comment about the quality of silicon used in SCR's many

years ago.

I had a couple extra so I replaced them. I now get 47.5 vdc.

BUT after a couple minutes the voltage started to fluctuate between roughly 45.5 - 47.5.

The problem seems to be heat related. When I spray the area around U1 with cold air it stops fluctuating for

another couple minutes. I’m going to try to narrow it down to at least a couple components.

Brian

The SCR’s I ordered are from Vishay #VS-2N689 Mouser #884-2N689 (didn’t see a datasheet)

Interesting you mentioned the problems with the SCR’s.

I bought an NOS VR on EBay a couple years ago. I tried it

shortly after I purchased it. It worked great for about 3 seconds then the generator

shut down with an over voltage condition. I put it away until I had time to deal with it.

I checked it out this morning.

I ran the three tests today and the 2[SUP]nd[/SUP] test failed. I was expecting 48 vdc and got 31.3 vdc.

I used the good VR to test against the bad one. Resistance comparisons loosely pointed to

a bad Q1. I also compared voltages at the junction of R5 / VR1 and R18 / R19. Got

a couple readings that were about 40% to low compared to the working VR. I was suspecting

the SCR’s but hesitated until I saw your comment about the quality of silicon used in SCR's many

years ago.

I had a couple extra so I replaced them. I now get 47.5 vdc.

BUT after a couple minutes the voltage started to fluctuate between roughly 45.5 - 47.5.

The problem seems to be heat related. When I spray the area around U1 with cold air it stops fluctuating for

another couple minutes. I’m going to try to narrow it down to at least a couple components.

Brian

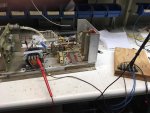

Peter,I marked a few things to check in the pic below. This is a typical Cap or Zener issue. My best guess would be one of the small electrolytic's is going bad, but could be a film too. We call this behavior motor boating when a cap starts to go bad - this is a similar pattern of what C2 looks like it when it starts to fail.

It is usually a cap used to stabilize a pin on semi conductor which has connection to Ground Plane and when they dry out they start to shorten the pin of the semi conductor to Ground. Little at first like in your case. The cap will heat up in the process because of the changing internal resistance or ESR which is normally near infinite Ohm at DC. So, you would need a ESR tester, capacitance check alone will not tell the full tail here.

But it also could be a deteriorating Zener where the silicone is starting to break down - that causes Voltage Fluctuations as well