I just picked up two 804A gensets. One has 2600 hrs, starts up runs great, output very good, just a little rusty.

The second I am having issues with. It has 3hrs on the meter and tag says rebuilt at 2.7 hrs in 2011. I installed new batteries, and it would not crank from S1 or Dead Crank switch. I traced that back to the K2 relay, it was a little corroded, cleaned it now starts and runs good.

When first running, the voltage on meter was good but frequency can only be adjusted between 43 and 53 Hz.

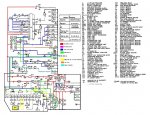

Now I get very low voltage amybe 25 and no frequency on the meter. I have tried holding S1 a little longer, upto 20 seconds but unit still has no output and the starter will stay engaged. I checked the MPU and it reads 3.4 volts the same as the good running unit. I will get voltage in Battle Short mode but frequency stays low. I assume that the MPU signal is not being recognized thus no starter disengagement or field flash.

What should I check next? I can't find anything in the TM, I'm sure it there somewhere just not that familiar with them yet.

The second I am having issues with. It has 3hrs on the meter and tag says rebuilt at 2.7 hrs in 2011. I installed new batteries, and it would not crank from S1 or Dead Crank switch. I traced that back to the K2 relay, it was a little corroded, cleaned it now starts and runs good.

When first running, the voltage on meter was good but frequency can only be adjusted between 43 and 53 Hz.

Now I get very low voltage amybe 25 and no frequency on the meter. I have tried holding S1 a little longer, upto 20 seconds but unit still has no output and the starter will stay engaged. I checked the MPU and it reads 3.4 volts the same as the good running unit. I will get voltage in Battle Short mode but frequency stays low. I assume that the MPU signal is not being recognized thus no starter disengagement or field flash.

What should I check next? I can't find anything in the TM, I'm sure it there somewhere just not that familiar with them yet.