for clarification:

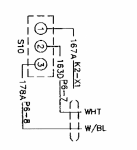

@Rik made a jumper wire from S10(1) to K2(X1) first to check this connection

S10(2) showed 25V on meter

then he pushed S10 to crank and no crank and Voltage on S10(2) dropped from 25V to around 7V

S10(2) is the 24V supply which is toggled by S10 between crank test and normal meaning supplying 24VDC to cubicle

when

@Rik applied a jumper wire directly from a good known source of 24V to S10(2) and put S10 into normal position then he was able to start run power stop Genset as usual

S10(2) is the com contact and wire 163D connects to MT4(1) and from there to FU1(1)

FU1 is a 25A DC Circuit Breaker

we have encountered several of these type of dc circuit breakers causing problems due to old age.

View attachment 895267

The one leg starts to make a poor contact internally increasing Resistance between both legs. Eventually this one leg just breaking off due to vibration.

we have found this issue on both 7.5A and 25A breakers

the MT4 issue as described by

@Guyfang I have not seen yet, but I am sure it’s lurking out there