The guy in that vid, IIRC, is running the electric backup pump as his sole booster.

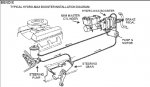

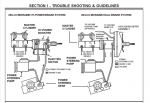

The airpack system on these trucks doesn't work like a standard modern power brake system. The master cylinder is directly operated by the pedal lever which sends fluid down to the separate airpack unit. This fluid movement operates a control valve which engages the airpack. The 'pack is a big air cylinder, pushed by the trucks compressed air supply, which in turn pushes on a second, integral, master which then pushes high pressure fluid out to the wheels. Its one line in and one out, with no provision for splitting.

Its an archaic system, i think it was developed by Midland even before the deuce, and was not often used on road going machines. It was generally used on construction equipment, like scrapers and wheel loaders, and it was phased out a long time ago.

*UPDATE* I just found out that Beaver/ Monaco built bus motorhomes into the 90's using multiple single pot masters run by air cans. Exactly the system we're thinking of!

Haldex Series III (p/n N37216C) referred to as the Haldex Pressure Converter.