vanaisa

Well-known member

- 275

- 372

- 63

- Location

- Tallinn, Estonia

I agree, they must be technically in order, exterior doesnt matter too much

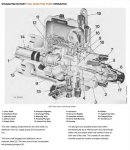

What is difference between "normal" and high altitude pump versions? Different fuel/air settings? If yes, can i change those settings myself?

What is difference between "normal" and high altitude pump versions? Different fuel/air settings? If yes, can i change those settings myself?