- 820

- 220

- 43

Hey everyone, working on my 1986 M1008. I just finished putting in a new fuel tank, sending unit, instrument panel flexiable circuit board, and other to finally get my fuel gauge working, as I had in another thread which I will be updating maybe later tonight.

In any case, when I was under the truck working on the tank, I used the rear tire to push my creeper around. Next thing I knew i had what looked like grease on my hand, so got to looking and saw a little bit of fluid leaking around rear drivers drum.

So I finished up with the fuel system yesterday and got it done early in the day. So I figured I'd go ahead and find out what was leaking on the drivers rear wheel. I pulled the tire, like to never beat it loose from the hub... didn't look that bad rusted or anything when I did get it off. Anyway, I found what appeared to be gear oil and dirt mixed making a grease like substance. So I knew it wasn't brake fluid and figuired it must be the axle seal leaking. Thought about just putting the tire back on and ordering an axle seal and differental cover seal as I saw it was damp around the bottom edge. But later decided to go ahead and pull the axle and drum... I'm glad I did... not what I was expecting. What a mess. Would have never known it was this bad from what little oil was on the backside of the hub.

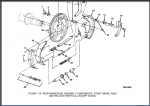

Like I said, quite the mess. With that said, I've done a few brake shoe and drum jobs, but its been a while. And I haven't worked on any setup quite like the CUCV drum and axle. When I first took the drum off, several peices fell out the bottom which I beleive to be part of the emergency brake, as well as its cable just hanging out toward the bottom of the hub. Also at least one spring is off or broken. Hard to tell exactly until I get everything cleaned up.

Next I started checking out the seal inside the drum and moved the bearings. I don't know if these bearings are supposed to be pressed in? But looking down at the drum like shown above, I can move both inner and outter bearings "up and down". They don't seem to have much slack side to side, which is where I would expect worn bearings would have. I can only assume it is normal to be able to moved them vertically though, as I do understand how they ride on the spindle shaft? on the hub.

I looked at where the bearings ride, cleaned it off some and although it looks like some wear spots on the shaft. I couldn't actually feel any inperfections. Except at the far back "wall", felt like some grooves there. Shown in the two photos below with the last having a red arrow.

So thats where I stopped yesterday. After putting the money in the fuel system, I really didn't want to spend any more $ on the truck right now. But this obviously can't wait, and I want to do it right and have it all fixed and not be redoing a job again.

First I need to get it all dissassembled and clean the entire hub and drum... probably will use at least 5 cans of brake clean for that I did take a paper towel and just clean off a section on the inside of the drum, and didn't feel any grooves or anything. But will have to clean the rest. The shoes have plenty "shoe" left on them, but I'm replacing them all anyway after being soaked in oil. I'm also going to replace the wheel cylinder, spring kit, seals (obviously), and might as well go ahead and replace the bearings too. I'm not sure if there is anything else I should replace or consider, so any input would be appreciated.

I did take a paper towel and just clean off a section on the inside of the drum, and didn't feel any grooves or anything. But will have to clean the rest. The shoes have plenty "shoe" left on them, but I'm replacing them all anyway after being soaked in oil. I'm also going to replace the wheel cylinder, spring kit, seals (obviously), and might as well go ahead and replace the bearings too. I'm not sure if there is anything else I should replace or consider, so any input would be appreciated.

I started looking through the TM's last night trying to figure out the correct parts... Can never figure out which manual will have what I'm looking for, so have to look through them all.

Going by the part numbers in the TM's, I've tried to cross them over using Rock Auto part # search. I'm not sure if I'm looking at the best replacment parts, or even the correct one's to be sure. From what I have read, when looking up parts by make/model instead of putting in the actual year we should look at what is listed for a 1984 K30 with the 6.2 disel. Due to this being a military truck and they didn't change parts for multiple years. I have tried this also, and usually come up with more part options than just by crossing the part #. I know some of the options will not match, but some of them do. Just different brands or etc that show being available that don't come up using just the part #.

In any case, here is what I have so far crossing the part # from the TM's using Rock Auto:

Wheel Hub Retainer/Lock Ring

TM 341511 - DORMAN 615141

Outter Wheel Bearing:

TM LM104949 - TIMKEN LM104949

* Race:

TM LM104911 - TIMKEN LM104911

Inner Wheel Bearing:

TM 387AS - TIMKEN 387AS

*Race:

TM 382A - TIMKEN 382A

Wheel/Axle Seal:

TM 469694 - TIMKEN 2081

**(I don't know what part # I crossed this from, but I also had a TIMKEN 8835S seal in the cart. I know I crossed this from another number out of the TM's last night, but now I can't seem to find it)

Wheel Cylinder:

TM 18004890 - RAYBESTOS WC37048

These below I looked up by Make/Model:

I don't know if bonded or rivited shoes are better?

**I am pretty sure the drums are 13 x 3.5"

Shoes:

ENTRIC 11104520 (bonded)

RAYBESTOS 452PG (rivited)

would rather have AC Delco, but they are twice the price.

Drum Hardware/Spring Kit (these kits does both wheels right?)

ACDELCO 18K561

Differental Cover Gasket for 10-1/2 IN Ring Gear, w/ 14 Bolt Holes:

MAHLE P28128 (paper)

DANA RD51995 (reusable "mechanically and chemically bonder woven steel")

I can't find a part # for the front Diff Cover (as I'm going to replace that one too when I change fluid), some threads on here said just use RTV.

To change the fluid in both front and rear differentals, looking at the FAQ's I think I'll need 5 quarts (10 pints) of 80w-90 gear oil?

Ok... sorry for such a long post. But does anyone else know of what else I might need?? Any opinions on any of this??

As I said, I've changed brake shoes before... I don't like them... and I've also never worked on this heavy of an axle before.

So Any input would be Greatly Apprciated

~Thanks All

In any case, when I was under the truck working on the tank, I used the rear tire to push my creeper around. Next thing I knew i had what looked like grease on my hand, so got to looking and saw a little bit of fluid leaking around rear drivers drum.

So I finished up with the fuel system yesterday and got it done early in the day. So I figured I'd go ahead and find out what was leaking on the drivers rear wheel. I pulled the tire, like to never beat it loose from the hub... didn't look that bad rusted or anything when I did get it off. Anyway, I found what appeared to be gear oil and dirt mixed making a grease like substance. So I knew it wasn't brake fluid and figuired it must be the axle seal leaking. Thought about just putting the tire back on and ordering an axle seal and differental cover seal as I saw it was damp around the bottom edge. But later decided to go ahead and pull the axle and drum... I'm glad I did... not what I was expecting. What a mess. Would have never known it was this bad from what little oil was on the backside of the hub.

Like I said, quite the mess. With that said, I've done a few brake shoe and drum jobs, but its been a while. And I haven't worked on any setup quite like the CUCV drum and axle. When I first took the drum off, several peices fell out the bottom which I beleive to be part of the emergency brake, as well as its cable just hanging out toward the bottom of the hub. Also at least one spring is off or broken. Hard to tell exactly until I get everything cleaned up.

Next I started checking out the seal inside the drum and moved the bearings. I don't know if these bearings are supposed to be pressed in? But looking down at the drum like shown above, I can move both inner and outter bearings "up and down". They don't seem to have much slack side to side, which is where I would expect worn bearings would have. I can only assume it is normal to be able to moved them vertically though, as I do understand how they ride on the spindle shaft? on the hub.

I looked at where the bearings ride, cleaned it off some and although it looks like some wear spots on the shaft. I couldn't actually feel any inperfections. Except at the far back "wall", felt like some grooves there. Shown in the two photos below with the last having a red arrow.

So thats where I stopped yesterday. After putting the money in the fuel system, I really didn't want to spend any more $ on the truck right now. But this obviously can't wait, and I want to do it right and have it all fixed and not be redoing a job again.

First I need to get it all dissassembled and clean the entire hub and drum... probably will use at least 5 cans of brake clean for that

I started looking through the TM's last night trying to figure out the correct parts... Can never figure out which manual will have what I'm looking for, so have to look through them all.

Going by the part numbers in the TM's, I've tried to cross them over using Rock Auto part # search. I'm not sure if I'm looking at the best replacment parts, or even the correct one's to be sure. From what I have read, when looking up parts by make/model instead of putting in the actual year we should look at what is listed for a 1984 K30 with the 6.2 disel. Due to this being a military truck and they didn't change parts for multiple years. I have tried this also, and usually come up with more part options than just by crossing the part #. I know some of the options will not match, but some of them do. Just different brands or etc that show being available that don't come up using just the part #.

In any case, here is what I have so far crossing the part # from the TM's using Rock Auto:

Wheel Hub Retainer/Lock Ring

TM 341511 - DORMAN 615141

Outter Wheel Bearing:

TM LM104949 - TIMKEN LM104949

* Race:

TM LM104911 - TIMKEN LM104911

Inner Wheel Bearing:

TM 387AS - TIMKEN 387AS

*Race:

TM 382A - TIMKEN 382A

Wheel/Axle Seal:

TM 469694 - TIMKEN 2081

**(I don't know what part # I crossed this from, but I also had a TIMKEN 8835S seal in the cart. I know I crossed this from another number out of the TM's last night, but now I can't seem to find it)

Wheel Cylinder:

TM 18004890 - RAYBESTOS WC37048

These below I looked up by Make/Model:

I don't know if bonded or rivited shoes are better?

**I am pretty sure the drums are 13 x 3.5"

Shoes:

ENTRIC 11104520 (bonded)

RAYBESTOS 452PG (rivited)

would rather have AC Delco, but they are twice the price.

Drum Hardware/Spring Kit (these kits does both wheels right?)

ACDELCO 18K561

Differental Cover Gasket for 10-1/2 IN Ring Gear, w/ 14 Bolt Holes:

MAHLE P28128 (paper)

DANA RD51995 (reusable "mechanically and chemically bonder woven steel")

I can't find a part # for the front Diff Cover (as I'm going to replace that one too when I change fluid), some threads on here said just use RTV.

To change the fluid in both front and rear differentals, looking at the FAQ's I think I'll need 5 quarts (10 pints) of 80w-90 gear oil?

Ok... sorry for such a long post. But does anyone else know of what else I might need?? Any opinions on any of this??

As I said, I've changed brake shoes before... I don't like them... and I've also never worked on this heavy of an axle before.

So Any input would be Greatly Apprciated

~Thanks All

Last edited:

I hate to even look up to see what they may cost.

I hate to even look up to see what they may cost.