- 1,886

- 1,474

- 113

- Location

- Laramie County, Wyoming

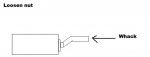

I just finished doing this very procedure to an M101A1. Nut had to be taken off with 3/4 inch electric impact wrench. Took about 5 minutes of pull the trigger and hold on before it came off. Next got big arsed pry bar and put it into the lunette. Note, the lunette cannot turn, it's sitting on a block to prevent that from happening. There is enough space though to get a little movement. Lifted one side, rotated to the other side, lifted and kept repeating until the tinniest movement was felt. Got out the BFH and applied 200lbs or so elbow grease and whacked the tar out of the threaded side. There is a feature on my lunette where you can beat the tar out of it and it won't reach the threads. After 4-5 solid whacks, it worked itself free. One more thing. There's a bolt on the top of my trailer hitch that appears to be somekind of lock for the lunette, got to remove that or the lunette aint coming out. Hope this helps. Not sure how relevant though with your M105.

Last edited: