Thanks. Yes, it really does appear to be "miracle juice"!

I was able to secure a "decarb set" of gaskets for $42. Here's the pic of what's included. From what I can tell, the only gasket not in this set is the crank case access panel one.

Lister Petter part # 657-34231

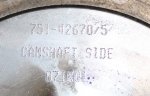

I was also able to score 2 "Joint Set" of gaskets from the same source for $55 a pop. They look as follows.

Lister Petter part # 657-34241

I'll check them out when I receive them to assess what else I need. Hopefully just that one crank case access panel gasket.

On the head gasket, looking at Lister Petter's web site, it looks like the current part number is 752-47171. I understand that there were issues with the early / older part number version, and that they have been corrected with the new ones?

I ask because Kraft Power only has 1 of these new ones left and there is a significant lead time (many months) on getting new ones.

There is a guy on Ebay selling aftermarket LPW2 head gaskets, but they cross to 752-40751, which appear to be the older part number before Lister fixed whatever the issue was with the original version(s)?

Here's a link:

http://www.ebay.com/itm/LPW2-Lister-Petter-Head-Gasket-/320471989418

I'm not sure if I should gamble on these aftermarket gaskets or pre-pay for 3 sets from Kraft and wait 16 weeks before getting them?