It passed the leak test. You can't tell from the photo, but the copper (or brass) washer was actually pretty smooth and nothing is leaking. So I put everything back together, filled with coolant, and it started leaking out the thermostat housing. Drained the coolant down a little and removed the housing. Turns out the area where the 2 bolts are is higher than the rest. So it was never going to seal. I checked a couple of the other thermostat housings on a piece of glass and they are all like that. So rather than waiting until next week and taking the housing to a machine shop to have them plane it flat, I opted to shave off some of the gasket instead.

http://www.cstone.net/~dk/MEP802-11-27-2015-01.JPG

http://www.cstone.net/~dk/MEP802-11-27-2015-01.JPG

I did both sides and kept test fitting until all the wiggle was gone. I then applied a thin bead of silicone sealant on both sides and put it back on. This time there was no leak when I added the coolant back. Of course the real test will be when its up and running at temp.

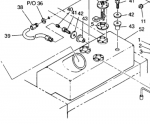

A couple of pics with the muffler and intake back on, ready for the first start up. As it turns out, the gasket kit does NOT include the exhaust gasket, so I had to use the one off the "part" unit. It was not in good shape and broke in half removing it, but its better than no gasket at all.

http://www.cstone.net/~dk/MEP802-11-27-2015-02.JPG

http://www.cstone.net/~dk/MEP802-11-27-2015-02.JPG

http://www.cstone.net/~dk/MEP802-11-27-2015-03.JPG

http://www.cstone.net/~dk/MEP802-11-27-2015-03.JPG

I then dead cranked it for a little while to build up oil pressure and topped off the oil again now that the oil filter was full. Next I let it prime fuel for about 5 minutes to let it circulate for a while. Finally, I did the bleed procedure by first letting the air out of the secondary fuel filter. What a pain it is getting to the bleeding screw. Next I did the bleeding at the injector pumps, and then tried to start it.

I was surprised that it started immediately. Frequency was just over 61 Hz, so I brought that down to 60. Then I noticed the whole unit starting walking across my shop floor so I shut it back down.

I hooked up a ground wire to the frame of my shop, and got out my crappy cell phone to take a little video of the 2nd starting. Sorry for the very poor cameraman-ship!

http://www.cstone.net/~dk/MEP802Running01.mp4

So it's not making any power and none of the gauges seem to be working. I was hoping to put it under load before letting it run a while to seat the new rings and the hone job I did. So I need to troubleshoot why its not making power. This is the 2nd of the 5 units that I now have running, neither of which is making power. I should not that I'm using the control box from the other running unit that was not making power, so maybe I'll swap control boxes first to see if that takes care of it.

Anything else obvious I should check as far as why this thing isn't making power? I will of course verify with a volt meter that I have no voltage at the terminals either in case the volt meter is bad. In a way, I hope that's all it is, but I probably won't be that lucky.