spicergear

New member

- 2,307

- 27

- 0

- Location

- Millerstown, PA

Two years or so ago I purchased a full front winch set up from m16ty. Great unit, great seller!

Time has come to fit it to the truck. I'm not a huge fan of how the bumper is set way out on the winch trucks...ANY of them, so wanted to make this easy to put on or off. The truck's four shackle mounts at the front of the frame got the nod to be pinned to. I did a partially similar 10K Garwood mount on my Mog. These 20K's are big off the truck and need to be treated a little differently. This is the oil drive set up.

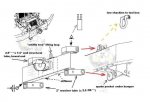

The pics don't show the motor, but you can see the top of the adapter that I trimmed to clear the bottom of the front bumper as this unit would slide back on to mount. Uses the same pins at the four clevises. Top tube is 2"x 6"x 1/4" wall, bottom tube is 3"x 3"x .375 wall. Winch mounting plates have been swapped side to side so the extension part would aim forward and will be trimmed off.

Still more welding to be done. I'm dumb...so I started welding bottom tubes on and winch side plate started to pull and bind my pins. You can see jackbolt I made up to push back to place then weld in bracing. Pretty happy with four point mount so far, have no concerns of strength issues with this set up either...plus bumper stays in place.

Time has come to fit it to the truck. I'm not a huge fan of how the bumper is set way out on the winch trucks...ANY of them, so wanted to make this easy to put on or off. The truck's four shackle mounts at the front of the frame got the nod to be pinned to. I did a partially similar 10K Garwood mount on my Mog. These 20K's are big off the truck and need to be treated a little differently. This is the oil drive set up.

The pics don't show the motor, but you can see the top of the adapter that I trimmed to clear the bottom of the front bumper as this unit would slide back on to mount. Uses the same pins at the four clevises. Top tube is 2"x 6"x 1/4" wall, bottom tube is 3"x 3"x .375 wall. Winch mounting plates have been swapped side to side so the extension part would aim forward and will be trimmed off.

Still more welding to be done. I'm dumb...so I started welding bottom tubes on and winch side plate started to pull and bind my pins. You can see jackbolt I made up to push back to place then weld in bracing. Pretty happy with four point mount so far, have no concerns of strength issues with this set up either...plus bumper stays in place.

Last edited: