ldmack3

Well-known member

- 849

- 1,740

- 93

- Location

- N. Central Idaho

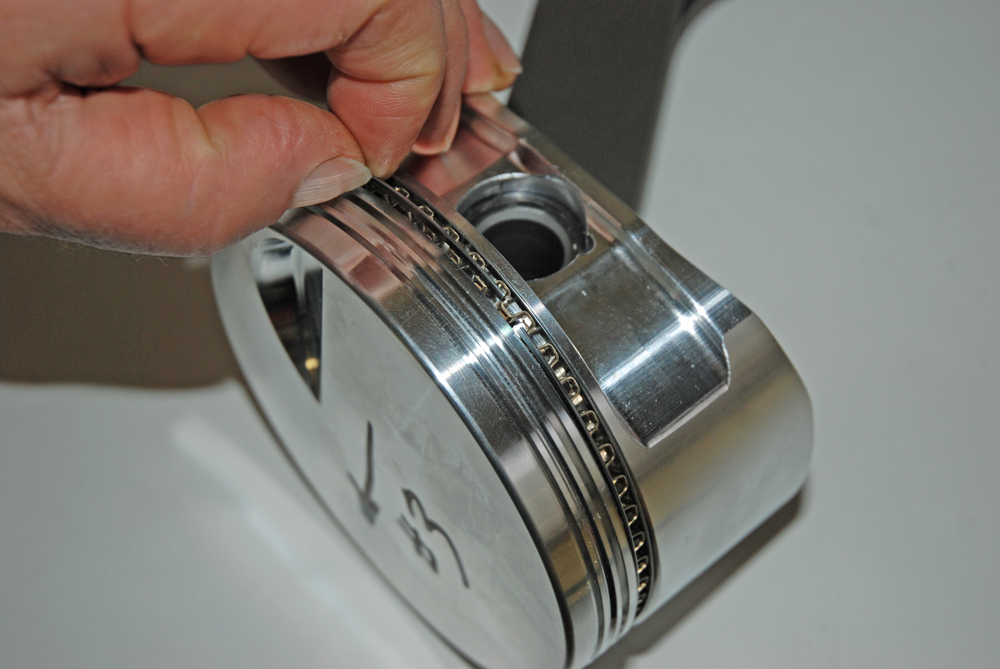

I'm replacing my upper rod end bearing sleeves need they need to be honed to fit the new pins/pistons.

The machine shop is asking for a rod center to center measurement which I cannot find in the TMs.

I've got 3 TMs on the engine but nothing going to this detail.

Is there a depot level/overhaul TM available that might have this or does anyone know?

Herc LDT-465-1D

Thanks

The machine shop is asking for a rod center to center measurement which I cannot find in the TMs.

I've got 3 TMs on the engine but nothing going to this detail.

Is there a depot level/overhaul TM available that might have this or does anyone know?

Herc LDT-465-1D

Thanks