rustystud

Well-known member

- 9,361

- 3,257

- 113

- Location

- Woodinville, Washington

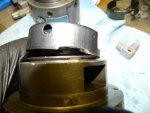

I'm in the process of rebuilding two Injection pumps. Since I don't have an installer for this bearing on the pump "cam shaft" and I don't want to spend the money on having one made I will use a trick I learned years ago and I thought I would share it with everyone here. First you take the part that will receive the bearing in this case the injection camshaft and put it in the deep freeze. For best results keep it in overnight. In picture one you see the part in a "zip lock" bag in my freezer. Then using a piece of pipe and my "heat gun" I heated up the bearing ( use low heat ! you only want the bearing heated up to about 250 degrees ) . This should only take a minute, literally ! Then having the frozen part securely held ( like in the vise) you quickly transfer the heated bearing onto the shaft. It should seat all the way immediately. Then using some lubricant ( I use "Tri-Flow" ) spray the bearing to cool it down. Picture seven shows the bearing fully installed on the shaft without any hammering or prying of any kind. This process also helps the shaft and bearing by not applying any pressure on them and actually "scuffing" the surfaces. At work we use this trick on all wheel bearing races that go into the hub and on the "MAN" buses since they love to use "press fit" bearings on everything. I guess it is a German engineering thing.

Last edited: