A quick follow up for others (like me) who haven't done this particular job before . . .

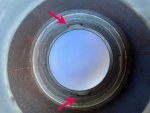

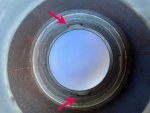

After finally cleaning all the old grease out of the hub, I discovered that there are two cutouts to provide surfaces to seat a punch.

I used the oval-head punch so I was able to work all the way around and keep the race fairly well aligned. Some races (cups) popped out easier than others, but none were difficult. Lighter "taps" with a 3 Lb. hammer seemed to work better.

Here's one of the old races compared to a new race:

I've read numerous times that the drum assemblies are heavy, but no one ever mentions the actual weights. Fun facts: The front drum assembly is 83 pounds. The rear assembly is 87 pounds.

I'd planned to use a hydraulic press to seat the new races, but discovered that the frame of my press is a little too narrow. There are lots of different ways to seat a new race, but I wanted to use a properly sized installer. I had a difficult time finding one, but eventually came across one made by Torque King:

From their ad:

Tech Note 3: Custom Fit:

QT1807 Bearing Cup Installer is made to install these Timken Taper Bearing Cup numbers: 3920, 39520.

I paired that installer with their 1116 handle and had excellent results. Note: I have no connection to Torque King other than this one purchase.

On a related topic, I had a difficult time removing the rear, inner axle seals and bearings. When I finally got them off I found that the spindles had been damaged by earlier maintenance (it wasn't me . . . honest):

I was able to file the surfaces to remove the burrs, but I'd like to avoid that problem in the future. Can anyone recommend a tool or technique for removing the inner (dust) seal?

Thanks